In the big world of industrial infrastructure, think of gate valves like silent guards. They quietly control the important liquids that keep our modern society running, whether it’s managing fluids in big industrial pipes or regulating the water in our homes. Gate valves might not get a lot of attention, but they play a huge role in how liquids move around.

This blog post is like a journey into the world of gate valves. It talks about their long history, how they’ve changed from simple tools to sophisticated devices, and why they’re so important today. Gate valves have been around for a really long time, and they’ve evolved to keep up with our changing technology.

As we go through the post, we’ll learn about the different parts of gate valves, how they’re crucial in industries like oil and gas, and even how they work to control the flow of liquids precisely. By the end of the journey, you’ll have a deep understanding of how these quiet gate valves are a key part of making sure our modern world keeps running smoothly..

Chapter 1: A Historical Perspective

- Ancient Origins of Fluid Control: Delve into the historical origins of fluid control mechanisms, examining early examples of valves in ancient civilizations, including the rudimentary sluice gates used in irrigation and water management.

- Medieval Advancements and Early Innovations: Explore the developments during the Middle Ages, including the use of wedge-shaped gates for regulating water flow in mills and industrial settings. Discuss how these innovations laid the foundation for modern these valves.

- Industrial Revolution: Gate Valves in Transition: Detail the crucial role played by these valves in the Industrial Revolution, where advancements in manufacturing and industrial processes drove the need for more efficient fluid control systems, leading to the refinement of gate valves as we know them today.

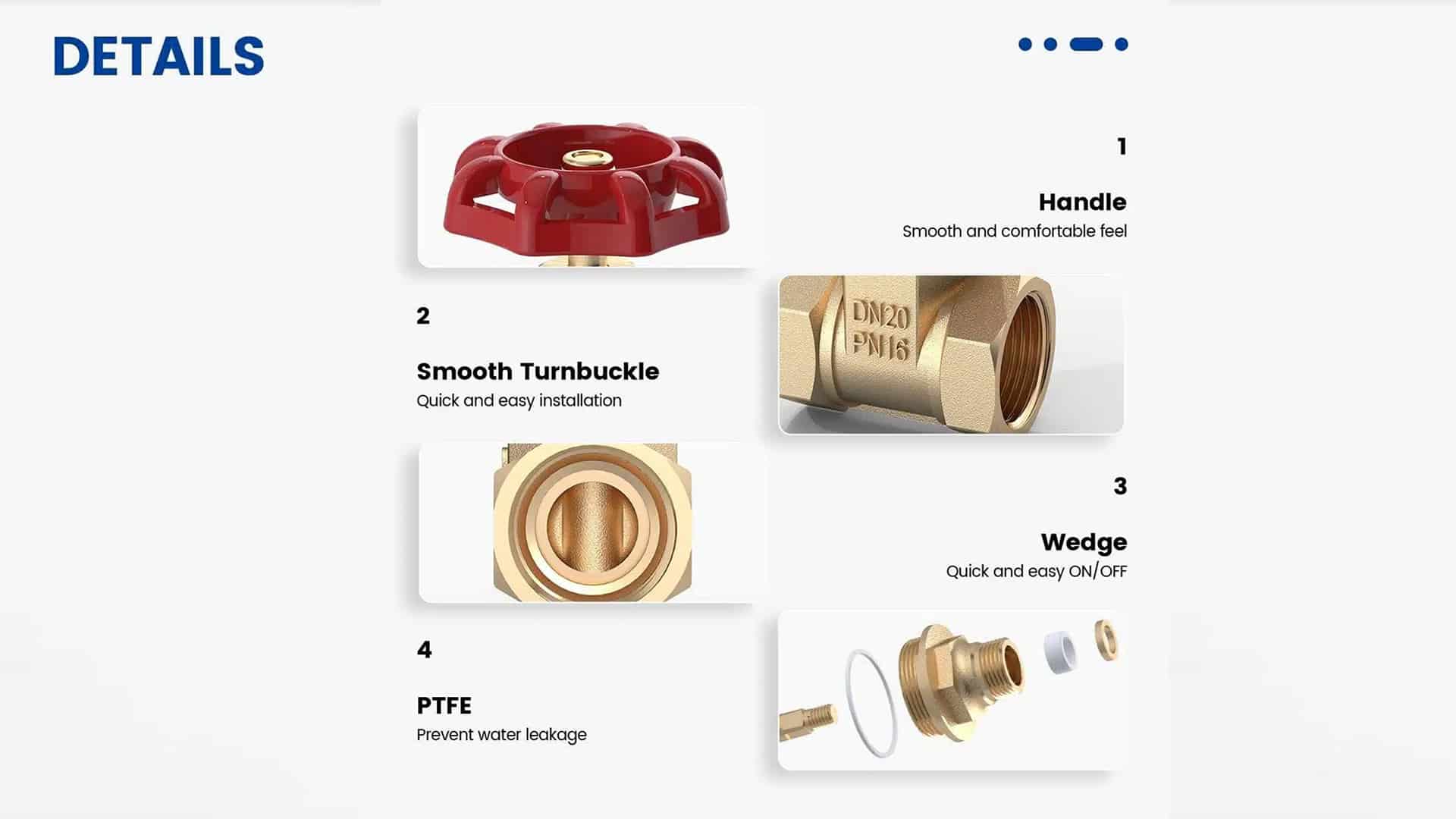

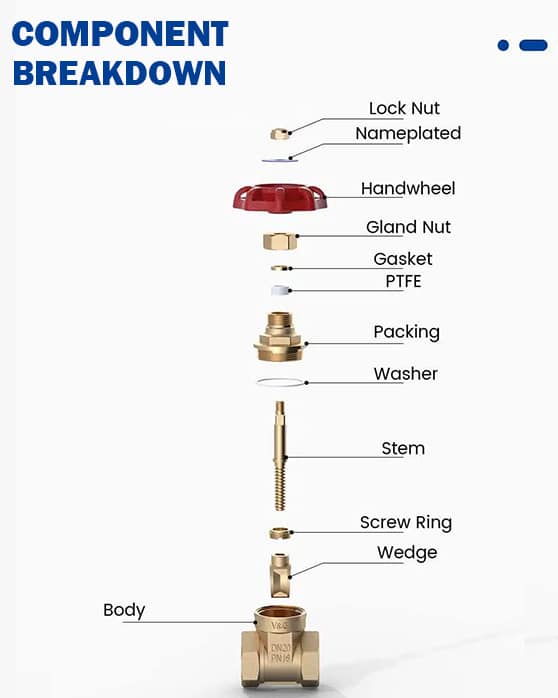

Chapter 2: Anatomy of a Gate Valve

- Valve Body: The Foundation of Fluid Control: Explain the significance of the valve body as the core structure of the gate valve, responsible for containing the fluid and providing a pathway for flow control.

- Bonnet and Stem: Linking Structure and Control: Discuss the dual function of the bonnet as a cover for the valve internals and the stem that connects the actuator to the gate. Explain how these components are crucial for both structural integrity and operational control.

- Gate and Seat: Precision Flow Control: Explore the gate and seat in detail, highlighting how the gate’s positioning against the seat determines the degree of flow control and sealing within the valve.

- Actuator Types: Diverse Control Mechanisms: Describe the various types of actuators used with these valves, from manual handwheels to motorized or pneumatic actuators. Explain how the choice of actuator affects the ease and precision of gate control.

Chapter 3: Applications and Variations

In this chapter, we’re going to explore how gate valves are used in different situations and the various types of gate valves that exist.

Common Applications of Gate Valves:

Gate valves are like multitasking superheroes in the industrial world. They’re not just limited to one job! In the oil and gas industry, they’re the go-to for controlling the flow of hydrocarbons, the stuff that powers a lot of our world. Water treatment plants also rely on gate valves to manage fluids during different treatment processes. And surprise, surprise – they even have a role in our homes! In residential plumbing systems, gate valves are the unsung heroes that isolate and control the water supply.

Types of Gate Valves and Their Functions:

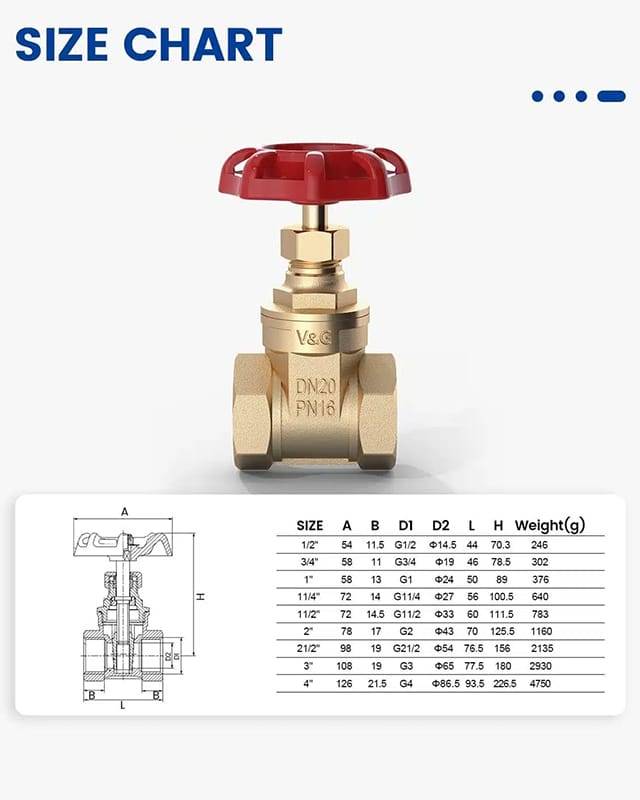

Gate valves come in different types, each with its own superpowers. There are rising stem and non-rising stem valves – they might sound like characters from a sci-fi movie, but they’re just different ways the valve opens. Some gate valves wedge tight to make sure nothing gets through when they’re closed, while others use parallel disc designs for smooth control of the liquid flow.

Material Selection in Gate Valves:

Picking the right material for gate valves is like choosing the right tool for the job. It’s a big deal! Depending on where the valve is going to work, you might need different materials. Think about it like this: if the fluid is hot or under a lot of pressure, you’d want a tough material like stainless steel. For other situations, materials like cast iron or bronze might be just right. This chapter is like a guide on how to choose the perfect superhero suit for your gate valve based on what it’s going to face – be it heat, pressure, or the kind of liquid it’s dealing with.

Chapter 4: The Ingenious Mechanism Behind Gate Valves

Chapter 4 explores the intricate mechanisms at play within gate valves. Thesevalves operate on a simple yet effective principle of linear motion. When the valve is open, the gate is raised, allowing fluid to flow through. Conversely, when the valve is closed, the gate is lowered, blocking the flow.

The sealing mechanism is a critical aspect of these valve operation. When the gate is lowered, it presses against the seat, creating a tight seal that prevents the passage of fluid. This design ensures that these valves are capable of providing excellent shutoff, making them invaluable in applications where leakage is unacceptable.

Position indicators on these valves offer operators a visual cue regarding the gate’s status, whether it’s open or closed. This feature enhances safety and control in industrial settings.

These valves are controlled using various types of actuators. Manual gate valves are operated by turning a handwheel, while automated these valves can be actuated by electric motors, pneumatic systems, or hydraulic mechanisms. These actuators enable precise control over the gate’s position, making gate valves versatile in a wide range of applications.

Chapter 5: The Importance of Sealing

Effective sealing is a fundamental aspect of these valves. Two primary types of seals are used in these valves: resilient and metal-to-metal seals. Resilient seals, often made of rubber or elastomeric materials, provide a reliable seal against the gate. They are known for their resilience and adaptability to varying pressures and temperatures. Metal-to-metal seals, on the other hand, offer a robust seal that is particularly effective in high-pressure and high-temperature applications.

The sealing mechanism in these valves ensures that when the gate is lowered, it makes contact with the seat, creating a tight closure. This feature is essential to prevent leaks and maintain the integrity of the system. The choice of seal depends on the specific requirements of the application and the properties of the fluid being controlled.

Chapter 6: Advantages and Limitations of Gate Valves

These valves come with a set of advantages and limitations that are crucial to consider when choosing them for a specific application. On the positive side, these valves are highly reliable, known for their ability to provide a tight shutoff, making them ideal for situations where even the smallest leak is unacceptable. Additionally, they boast a low-pressure drop, ensuring minimal impact on fluid flow and proving to be efficient in high-flow scenarios.

However, they do have their drawbacks. These valves operate relatively slowly compared to other valve types, which might be a downside in applications requiring a rapid response. Moreover, they can be vulnerable to damage in high-velocity flow situations, where the force of the fluid rushing through may lead to erosion and wear over time. Therefore, careful consideration of these advantages and limitations is essential when selecting these valves for a particular application.

Conclusion

Gate valves are an integral part of our world, silently ensuring the smooth operation of critical systems we rely on every day. From their historical origins to the complex mechanics that enable their precise operation, understanding gate valves is essential for engineers, homeowners, and anyone interested in the inner workings of infrastructure. As we look to the future, these valves will undoubtedly continue to evolve and adapt to meet the ever-growing demands of our modern world, making them a fascinating subject to explore.

1 Comment