Many people mix up manifolds and manifold sets because their names sound similar. These two tools do very different jobs in plumbing, HVAC and refrigeration. Knowing manifold vs manifold set differences helps you pick the right one and work more efficiently and safely.

This article explains what a manifold does, what a manifold set does and how they differ. It also tells you when to use each so you get the best results.

What Is a Manifold?

A manifold works like a central hub in plumbing or heating systems. It splits water, gas or air from one main pipe into several smaller pipes. Sometimes, it collects fluid from many small pipes into one big pipe. This design helps control the flow in complex systems.

Most manifolds use brass, stainless steel or plastic. They have one or more inlet ports and many outlet ports. Each outlet has a valve to control or stop flow in that branch. This setup helps you adjust flow easily and do maintenance without shutting down the whole system.

For example, a home heating manifold sends hot water from the boiler to different rooms. You can adjust each room’s heating independently. You can also find manifolds in compressed air lines, irrigation systems and plumbing setups that need flow control in many places.

Manifolds keep the system organized. They reduce the need for many valves and make fixing problems faster and easier.

What Is a Manifold Set?

A manifold set is a tool HVAC and refrigeration technicians use. Unlike fixed manifolds, this tool connects temporarily to cooling systems for testing and repair.

A manifold set has a metal block with pressure gauges. Usually, it shows low and high pressure. It also has three hoses: red, blue and yellow. These connect to parts of the refrigeration system. Valves on the manifold let the technician control refrigerant flow during service.

Technicians use manifold sets to check pressure, find leaks, remove air, add refrigerant and monitor system health. This tool helps keep air conditioners and refrigerators running well. It ensures safe pressure levels and prevents damage from wrong refrigerant amounts.

Manifold sets give precise readings and control. They make diagnosis and repair easier and safer.

Key Differences Between Manifold and Manifold Set

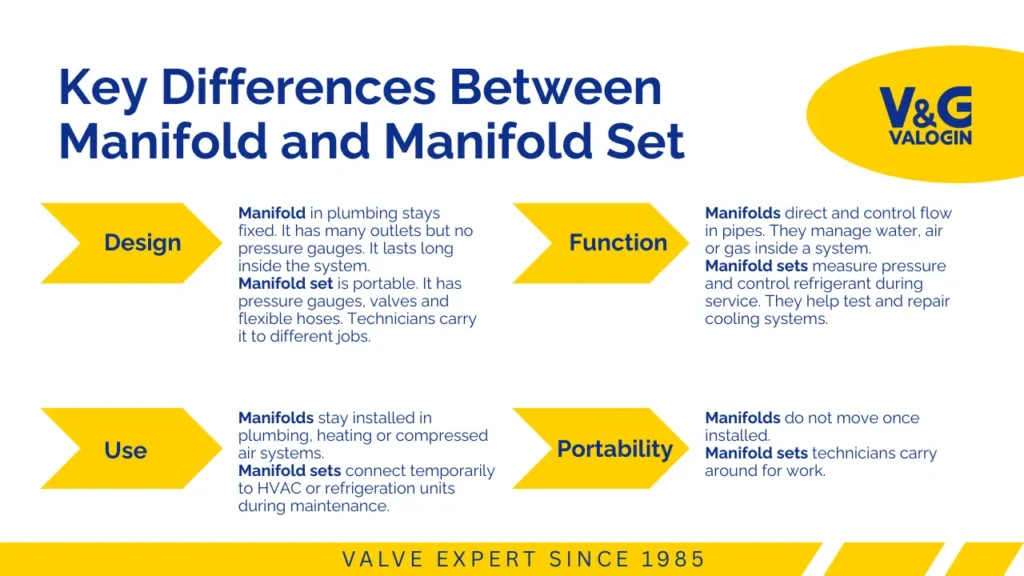

Manifolds and manifold sets look similar but differ in design, function and use.

Design:

A manifold in plumbing stays fixed. It has many outlets but no pressure gauges. It lasts long inside the system.

A manifold set is portable. It has pressure gauges, valves and flexible hoses. Technicians carry it to different jobs.

Function:

Manifolds direct and control flow in pipes. They manage water, air or gas inside a system.

Manifold sets measure pressure and control refrigerant during service. They help test and repair cooling systems.

Use:

Manifolds stay installed in plumbing, heating or compressed air systems.

Manifold sets connect temporarily to HVAC or refrigeration units during maintenance.

Portability:

Manifolds do not move once installed.

Manifold sets technicians carry around for work.

Knowing these differences helps you avoid mistakes and pick the right tool.

When to Use a Manifold

Use a manifold when you want to control and split fluid or gas flow inside a pipe system. Manifolds work well in homes and businesses for heating, plumbing and air distribution.

For example, hydronic heating uses a manifold to send hot water to different zones. Each zone gets the right flow and temperature. You can turn off one zone without affecting others.

Manifolds reduce pipe clutter and make fixing leaks easier. They help balance flow and save energy.

Choose brass or stainless steel manifolds for durability and long life, especially in tough environments.

When to Use a Manifold Set

Use a manifold set when working on HVAC or refrigeration systems. This tool helps you check and fix air conditioners, refrigerators, chillers and heat pumps.

Use the set to measure pressures, check for leaks, remove air or moisture and refill refrigerant safely. Without it, you cannot keep these systems healthy or fix problems properly.

Technicians rely on manifold sets to find faults, balance refrigerant and keep cooling systems efficient.

Refrigeration systems run at high pressures and use special gases. A manifold set gives accurate control and readings to prevent damage and ensure safety.

If you repair cooling systems regularly, buy a good manifold set. It makes your work easier and faster.

Conclusion

Manifolds and manifold sets serve different jobs in fluid control.

Manifolds stay fixed inside plumbing or heating systems. They control and split water or gas flow.

Manifold sets are portable tools. Technicians use them to check and fix HVAC and refrigeration systems.

Knowing these differences helps you pick the right tool for your job. Use manifolds to manage flow inside pipes. Use manifold sets to measure and service cooling systems.

Choosing the right tool improves safety, performance and lifespan of your systems. Whether you install plumbing or repair HVAC, understanding manifolds vs manifold sets helps you work smarter.