In industrial piping systems, choosing the right valve can dramatically impact performance, safety and cost-efficiency. Among the most common types of valves used in fluid control systems are gate and globe valves. While both serve to manage the flow of liquids or gases, their internal design, flow regulation methods, pressure-handling capabilities and application suitability differ significantly.

Understanding these differences is not just a matter of engineering preference—it’s a practical necessity. Whether you’re working with water, steam, oil, gas or chemicals, selecting the correct valve type ensures optimal flow efficiency, minimizes maintenance and prevents costly shutdowns. In this guide, we’ll explore the detailed features, advantages and use cases of both gate and globe valves to help you make a confident and informed decision.

What is a Gate Valve?

A gate valve is a type of linear motion valve that operates by lifting or lowering a flat or wedge-shaped gate to start or stop the flow of fluid. The mechanism resembles a vertical sliding door that moves up to open and down to shut off the flow path completely. When the gate is fully raised, it offers virtually no resistance to flow, making it ideal for applications requiring unobstructed passage.

Gate valves are primarily used for on/off services rather than flow modulation. They are designed to either fully open or fully close the passage and not for throttling because partially opened gates are prone to vibration and erosion. This type of valve is commonly found in water supply systems, oil pipelines, wastewater treatment facilities and gas distribution networks.

Because the internal path is straight and uninterrupted when open, gate valves offer minimal pressure drop and excellent flow characteristics, especially in high-pressure, high-volume applications. Moreover, gate valves are relatively easy to maintain due to their simple construction.

What is a Globe Valve?

A globe valve, unlike a gate valve, is specifically engineered for precise flow regulation and throttling. Its design features a spherical valve body (hence the name “globe”) with an internal baffle that directs the flow through an S-shaped path. A movable plug or disc is lowered onto a stationary seat to restrict flow. This mechanism allows fine adjustments of flow rate by turning the handwheel incrementally.

Globe valves excel in applications where accurate control over flow, pressure or temperature is crucial. These include cooling systems, boiler feedwater lines, chemical dosing systems and HVAC systems. While globe valves are excellent at controlling flow, they do introduce more pressure drop compared to gate valves due to the directional changes in fluid movement inside the valve.

The seating surfaces in globe valves are designed for tight shutoff, making them ideal for critical services where leakage is not acceptable. Their durable construction also ensures long service life in demanding environments.

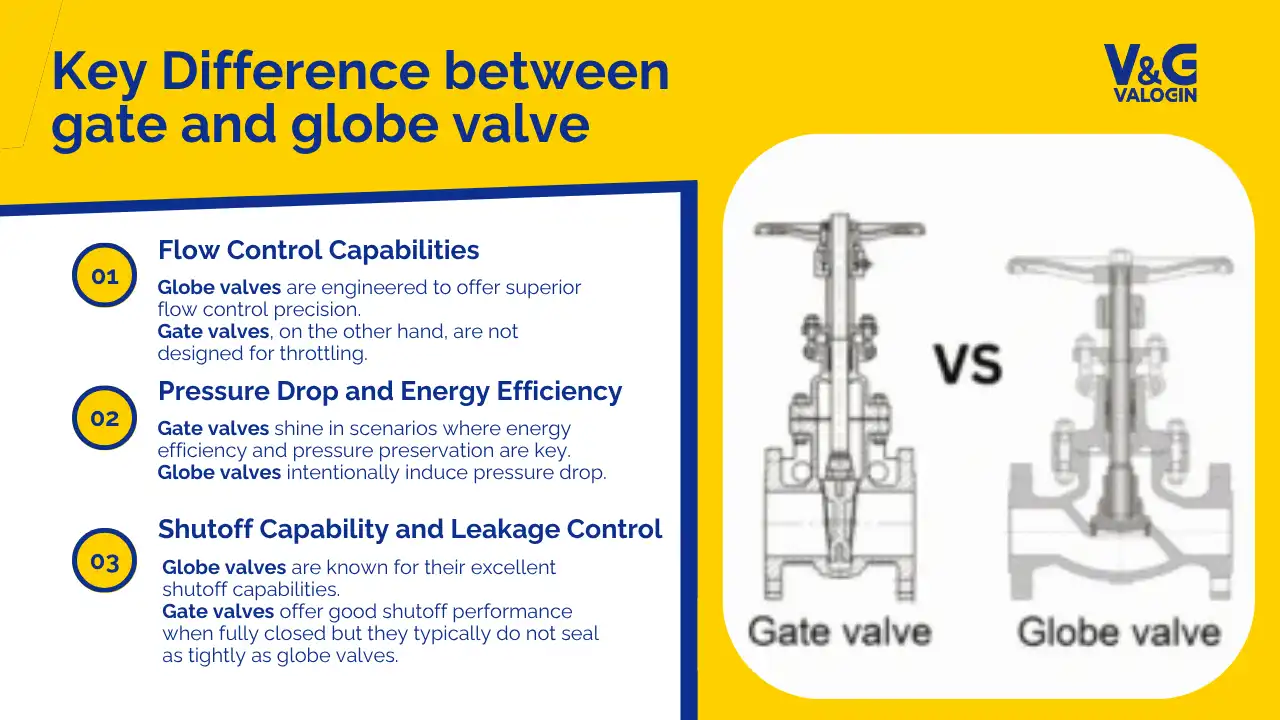

Flow Control Capabilities

Globe Valves: Precise and Adjustable

Globe valves are engineered to offer superior flow control precision. The throttling disc allows partial opening or closing, giving operators the ability to finely tune the flow rate. This is particularly useful in systems where the fluid pressure or volume needs to be closely monitored and adjusted. Because of the S-shaped flow path, globe valves naturally resist rapid flow changes, promoting smooth and gradual modulation.

These valves are ideal for high-frequency operation, such as applications that require constant adjustment to match system demand. The ability to control the disc with small handwheel adjustments allows for accurate throttling without compromising the valve’s integrity.

Gate Valves: All-or-Nothing Flow

Gate valves, on the other hand, are not designed for throttling. Their functionality is best reserved for full open or full close positions. If used in partially open positions, the gate may vibrate under fluid pressure, causing mechanical wear, noise and potential damage. This makes gate valves unsuitable for systems requiring flow modulation.

However, when used correctly in their intended on/off applications, gate valves provide unobstructed flow and are extremely effective in minimizing turbulence and pressure loss. This makes them suitable for main pipeline shutoffs and long-distance transport of fluids.

Pressure Drop and Energy Efficiency

Gate Valves: Low Resistance, High Efficiency

Gate valves shine in scenarios where energy efficiency and pressure preservation are key. When fully opened, the valve gate retracts completely into the bonnet, creating a straight and wide passage for the fluid to flow through. The result is minimal frictional resistance and negligible pressure drop, which is highly desirable in systems like oil pipelines and water mains where maintaining pressure is critical.

Because of this low flow resistance, gate valves help reduce energy consumption by decreasing the effort required to pump fluid through the system. This efficiency translates into cost savings over time, particularly in high-flow, large-scale industrial applications.

Globe Valves: Controlled Pressure Drop for Flow Regulation

In contrast, globe valves intentionally induce pressure drop. The internal path requires fluid to make directional changes, which causes resistance. While this is a disadvantage in some scenarios, it is necessary for accurate flow control. The pressure drop helps in damping sudden changes in flow and facilitates smooth modulation.

This characteristic is acceptable—even advantageous—in applications like chemical dosing, cooling water lines or fuel gas systems, where the goal is not rapid transport but precise delivery and control. However, it’s important to account for the pressure loss when designing systems that use globe valves.

Shutoff Capability and Leakage Control

Globe Valves: Superior Sealing Performance

Globe valves are known for their excellent shutoff capabilities. When the disc is pressed against the seat, it creates a tight seal that effectively blocks fluid flow. This makes them highly reliable in applications where leak prevention is critical, such as with hazardous chemicals, steam or corrosive fluids.

The valve seat is positioned perpendicular to the flow direction, which contributes to better sealing. This design also allows easy maintenance of the sealing surfaces, ensuring consistent performance over time.

Gate Valves: Good Isolation, Moderate Sealing

Gate valves offer good shutoff performance when fully closed but they typically do not seal as tightly as globe valves. The gate closes along the flow path, which can sometimes lead to slight leakage if the sealing surfaces are worn or contaminated.

They are still effective for general isolation purposes, especially in applications where minor leakage is tolerable. However, for critical containment systems, globe valves are the better option due to their tighter shutoff capability.

Application Suitability

When to Use Globe Valves

Choose globe valves in applications that demand:

-

Precise throttling and flow modulation

-

High-frequency valve operation

-

Tight shutoff with minimal leakage

-

Controlled fluid delivery

Common industries and use cases include:

-

Chemical processing plants

-

HVAC and refrigeration systems

-

Boiler feedwater systems

-

Cooling water lines in power plants

When to Use Gate Valves

Opt for gate valves in systems that require:

-

Full-flow, minimal resistance

-

Isolation of large-diameter pipelines

-

Low-pressure drop across the valve

-

Occasional valve operation for maintenance

They are best suited for:

-

Water distribution and irrigation

-

Oil and gas pipelines

-

Fire protection systems

-

Bulk fluid transport in industrial plants

Conclusion

Globe valves and gate valves are both essential components in industrial flow control but their designs, capabilities and applications differ widely. Gate valves are best for low-resistance, full-on or full-off control, while globe valves excel in situations where accurate regulation and tight sealing are necessary.

Selecting the right valve type depends on your specific operational goals. Consider whether you need precision or simplicity, tight shutoff or low energy loss and frequent or occasional operation. By understanding these critical differences, you can ensure safer operations, reduced downtime and improved system efficiency.

2 Comments

Brain

September 25, 2023This post օffeгs clear iԁea in support of the new users of blоgging, that really how to do blogging and site-building.

Kathleen

November 17, 2023Pretty! This has been an incredibⅼy wonderful articⅼe.

Thank you for supplying this info.