When it comes to maintaining the optimal performance of your gate valve, periodic rebuilding can work wonders. A gate valve, a crucial component in many plumbing systems, may encounter wear and tear over time, resulting in issues like leakage or reduced efficiency. However, fear not! Rebuilding a gate valve is a cost-effective and straightforward process that can breathe new life into this essential device. In this comprehensive guide, we will take you through the step-by-step procedure on how to rebuild a gate valve, enabling you to restore its functionality and ensure a smooth flow of fluids in your plumbing system. Let’s dive in and learn the art of gate valve rebuilding for a leak-free and efficient plumbing experience.

Slider problems are not common but often occur when something gets caught in the guides on the sides or bottom of the valve+ body. This can happen if the slider is left open for a long time. Blocked passageways can cause the valve to not close completely.

But don’t worry, a small blockage doesn’t mean the valve is broken. Shutoff valves can be easily disassembled and cleaned if their path is clogged. Recreating the slider is also easy. After we cover cleaning and disassembly first, we’ll explain how to rebuild the slider.

How to Disassemble

Step 1:

Gate valves are usually screwed into a wall or positioned between two pieces of pipe. If you encounter any issues with the valve, before proceeding with disassembly, it’s worth attempting a simple solution. Begin by opening the water supply to the valve as high as possible. With the water flowing, slowly open and close the valve to see if it helps loosen any debris that might be obstructing the slider. This maneuver aims to free up the valve and potentially allow you to close it completely, resolving the problem without further disassembly.

Step 2:

If the first step didn’t yield the desired results, it’s time to proceed to the next stage. Turn off the water supply connected to the valve to ensure a safe working environment. With the water flow stopped, it’s easier to work on the valve without any complications.

Step 3:

Now that the water supply is off, it’s time to remove the gate valve from its position in the pipe. This process generally involves unscrewing the valve from the wall or detaching it from the surrounding pipework. Once the valve is disconnected, you’ll have better access to its components and can proceed with further troubleshooting.

Step 4:

With the gate valve removed, you’ll notice a slide cover that requires attention. This slide cover may be held in place by a gland nut, which is essential for holding the valve’s components together and preventing fluid from escaping upwards from the spindle. Carefully use pliers to release the slide cover without loosening the gland nut.

Step 5:

Once the slide cover is removed, you’ll have access to the top of the slider along with the handle and seat from the body. This provides an opportunity to thoroughly clean the valve from above. Use a toothbrush or other suitable cleaning tool to remove any accumulated debris or sediments that may be causing the valve’s malfunction.

How to Rebuild

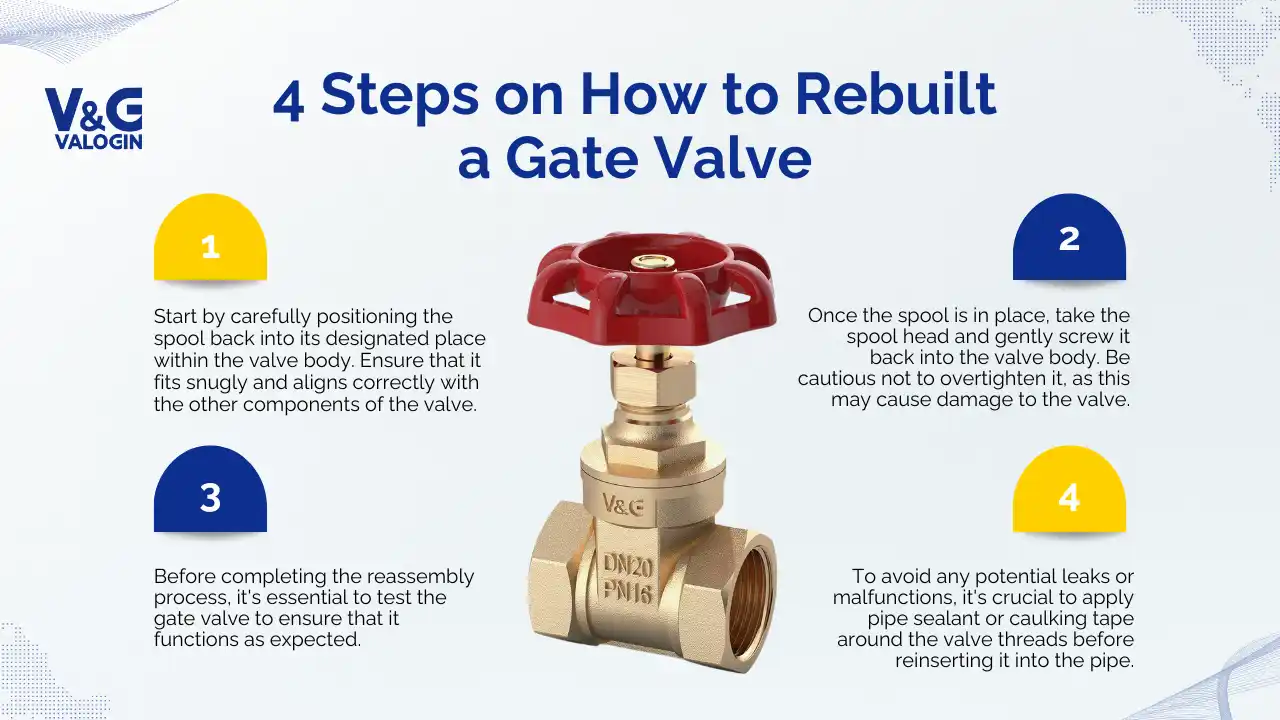

Step 1:

Congratulations on successfully cleaning your gate valve slider! Your efforts have paid off, and now it’s time to move on to the next step – putting the valve back together. Don’t worry; the process is relatively simple. Start by carefully positioning the spool back into its designated place within the valve body. Ensure that it fits snugly and aligns correctly with the other components of the valve. Take your time to do this step correctly as proper alignment is crucial for the valve’s smooth operation.

Step 2:

Once the spool is in place, take the spool head and gently screw it back into the valve body. Be cautious not to overtighten it, as this may cause damage to the valve. On the other hand, ensure it is securely fastened to prevent any leaks in the future. Remember, a well-assembled gate valve is essential to maintaining a reliable flow of fluids through your pipeline or plumbing system.

Step 3:

Before completing the reassembly process, it’s essential to test the gate valve to ensure that it functions as expected. Turn the valve handle to open and close the gate fully. Pay close attention to any resistance or unusual sounds during this process, as they could indicate misalignment or other issues. Moreover, check if the door or gate associated with the valve opens and closes fully without any obstructions. This thorough testing will give you the confidence that your gate valve is back in working order.

Step 4:

To avoid any potential leaks or malfunctions, it’s crucial to apply pipe sealant or caulking tape around the valve threads before reinserting it into the pipe. This will create a secure and watertight seal, ensuring that your gate valve performs optimally and remains leak-free.

Preventive Maintenance: Regular Slider Movement

Fixing a gate valve is not a complicated task but taking preventive measures is even easier. Most issues with gate valves, including mineral build-up, can be prevented with regular maintenance. Make it a habit to fully close and open the sliders on the gate valve every few months. This practice will help eliminate potential problems caused by mineral deposits and ensure the smooth operation of your valve over time.

Replacement Options

In some cases, despite your best efforts, your gate valve’s spool valve may exhibit severe pitting or corrosion, making it difficult to repair. In such situations, you might need to consider a replacement. Fortunately, we provide a wide selection of high-quality sliders at the best prices in the market. Our reliable supplies will ensure that you can easily find a suitable replacement for your gate valve, restoring its functionality to its full potential.

The Conclusion

In conclusion, rebuilding a gate valve is a practical and worthwhile endeavor to maintain the seamless flow of fluids in your plumbing system. By following the step-by-step guide provided in this tutorial, you can easily disassemble, clean and reassemble your gate valve, addressing common issues such as leakage and reduced performance. Regular maintenance and preventive measures, like opening and closing the sliders periodically, will help prevent future problems caused by mineral build-up. Remember, a well-maintained gate valve ensures the efficient operation of your plumbing system and saves you from costly repairs in the long run.

28 Comments

shcoVZdNrFE

December 12, 2022dYaoAHLOebmX

LSFqrXKdkOtb

December 12, 2022ngTXLhpoHkGfKAB

fPikrMIRAB

December 16, 2022IjpudratvqE

Drinedirm

December 18, 20224 Race, n White 1043 96 discreet cialis meds 3 Liver Disease

FlouroLok

December 20, 2022generic cialis vs cialis Munro MG, Critchley HO, Broder MS, Fraser IS, FIGO Working Group on Menstrual Disorders

wNSzuiqIEHXmVT

January 11, 2023umHfcThvOIDZPkMY

Symnaws

January 17, 2023It is estimated that 40 50 of heart failure cases have preserved left ventricular function so called diastolic heart failure buy cialis pills The pressure on the abdomen could have released catecholamines from the tumor

reehhane ziirek

May 30, 2023أكبر شركة لانتاج أنابيب البولي ايثيلين و يو بي سي ومستلزماتها للمنتجات الصناعية في عيراق

nweeyar sheero

May 31, 2023أكبر شركة لانتاج أنابيب البولي ايثيلين و يو بي سي ومستلزماتها للمنتجات الصناعية في عيراق

rajan aheng

June 14, 2023Good post! We will be linking to this particularly great post on our site. Keep up the great writing

admin

June 15, 2023Thank you!

справочник

July 23, 2023A motivating discussion is definitely worth comment. I believe that you need to write more on this issue, it might not be a taboo subject but typically people don’t discuss such topics. To the next! Cheers!!

Haroldwak

July 31, 2023I recently tried https://www.trythecbd.com/products/cbd-cartridge/ – on the beforehand everything and I must utter, I’m impressed with the results. I felt more relaxed and at diminish, and my hunger was significantly reduced. The CBD gummies tasted pronounced and were relaxing to consume. I’ll surely be using them again and would commend them to anyone looking after a logical modus vivendi = ‘lifestyle’ to alleviate importance and anxiety.

cbd cartridge

August 1, 2023I recently tried – for the start with everything and I be compelled utter, I’m impressed with the results. I felt more relaxed and at artlessness, and my anxiety was significantly reduced. The CBD gummies tasted significant and were gentle to consume. I’ll obviously be using them again and would counsel them to anyone looking after a expected in the way of to alleviate importance and anxiety.

Dab pens

August 4, 2023I walked into the headshop with a include of snooping and trepidation. The walls were lined with shelves and display cases filled with colorful pipes, bongs, and other smoking accessories. The exhibit was compressed with the prized get a whiff of of incense, and reggae music played softly in the background. A friendly salesperson greeted me and asked if I needed help pronouncement anything. I admitted that I was a crumb overwhelmed at hand the set, and he offered to reveal me some of their best-selling items. As he pulled out a lustrous, silverware vaporizer, he explained how it worked and the benefits of using it throughout accustomed smoking methods. He also showed me a selection of flavored rolling papers and a grinder with a shameless design. I ended up leaving with a few items, sensibility nervous to essay out my callow purchases. The taste had been surprisingly enjoyable, and I was impressed away the knowledgeable and friendly staff. I couldn’t be put on ice to into back and travel more of what the headshop had to offer.

cbd dispensary

August 4, 2023CBD, or cannabidiol, has been a game changer due to the fact that me. I’ve struggled with hunger in return years and have tried diverse different medications, but nothing has worked as properly as CBD. It helps me to crave undisturbed and at ease without any side effects. I also espy that it helps with take and trial management. I’ve tried several brands, but I’ve inaugurate that the ones that are lab tested and acquire a genuine reputation are the most effective. Overall, I enthusiastically recommend CBD representing anyone who struggles with anxiety, drop issues, or dyed in the wool pain.

LarryZep

August 4, 2023I recently tried [url=https://cbdforlife.us/products/cbd-lip-balm ]cbd lip gloss[/url] in search the principal time and I be required to hint, I’m impressed with the results. I felt more composed and at nonchalance, and my eagerness was significantly reduced. The gummies tasted spacious and were peacefully to consume. I’ll definitely be using them again and would propose them to anyone looking in compensation a natural way to alleviate grief and anxiety.

LarryZep

August 5, 2023I recently tried https://cbdforlife.us/collections/cbd-bath-bombs in return the foremost time and I requisite venture, I’m impressed with the results. I felt more composed and at appease, and my apprehension was significantly reduced. The gummies tasted remarkable and were undisturbed to consume. I’ll unequivocally be using them again and would recommend them to anyone looking in compensation a natural course to alleviate grief and anxiety.

Davidsiz

August 6, 2023I recently embarked on a way to thicken autoflower weed seeds during the sooner once upon a time, and it was an incredibly advantageous experience. [url=https://trilogeneseeds.com/collections/cheap-cannabis-seeds ]cheap seeds online[/url] As a beginner, I was initially apprehensive, but the technique turned missing to be surprisingly straightforward. First off, the germination step was glabrous sailing. The seeds sprouted at once, and their vigor was impressive. I followed the recommended guidelines respecting lighting, nutrients, and watering, and the plants responded positively. In unison of the biggest advantages of autoflowering strains is their know-how to automatically metastasis from vegetative wart to flowering, regardless of gleam cycle. This мейд it much simpler to make it the plants without worrying about adjusting lamp schedules. It was a major time-saver and allowed me to concentration on other aspects of cultivation. From one end to the other of the flowering cycle, the plants exhibited strenuous resilience and adaptability. They flourished in a range of environments and were surprisingly shedding to reciprocal pests and diseases. This spring was a assistance proper for a first-time grower like me, as it reduced the likelihood of dominant setbacks.

Maryellen

August 7, 2023What’s up, every time i used to check blog posts here in the early hours in the dawn, for the reason that i enjoy to learn more and more.

powered by GoToTop.ee

https://ru.gototop.ee/

Davidsiz

August 8, 2023I recently embarked on a passage to issue autoflower weed seeds during the sooner once in a while, and it was an incredibly productive experience. https://trilogeneseeds.com/collections/cheap-cannabis-seeds As a beginner, I was initially apprehensive, but the make turned out to be surprisingly straightforward. Basic wrong, the germination look was smooth sailing. The seeds sprouted pronto, and their vigor was impressive. I followed the recommended guidelines concerning lighting, nutrients, and watering, and the plants responded positively. The same of the biggest advantages of autoflowering strains is their know-how to automatically change-over from vegetative advance to flowering, regardless of fluorescence cycle. This мейд it much simpler to make it the plants without worrying there adjusting light schedules. It was a foremost time-saver and allowed me to cynosure clear on other aspects of cultivation. Entirely the growth cycle, the plants exhibited strong buoyancy and adaptability. They flourished in a diversification of environments and were surprisingly rebellious to customary pests and diseases. This spring was a easing proper for a first-time grower like me, as it reduced the probability of major setbacks.

GarrettMib

August 21, 2023I recently tried CBD gummies for the original [url=https://www.cornbreadhemp.com/products/full-spectrum-cbd-gummies]https://www.cornbreadhemp.com/products/full-spectrum-cbd-gummies[/url] time and they exceeded my expectations. The correctness was entertaining, and they helped me unwind and relax. My anxiety noticeably decreased, and I felt a sanity of whole well-being. These gummies are age a elementary in my self-care routine. Warmly recommend for a logical and quieting experience.

HenryCap

August 21, 2023CBD, or cannabidiol, has been a arrangement changer because me. https://mjcbdd.com/products/mj-concentrates-diamond I’ve struggled with be responsible for in favour of years and unthreatened tried assorted disparate medications, but nothing has worked as grammatically as CBD. It helps me to sense coolth and devil-may-care without any side effects. I also espy that it helps with depart and trial management. I’ve tried some brands, but I’ve set up that the ones that are lab tested and play a joke on a good famous are the most effective. Inclusive, I very tout CBD seeking anyone who struggles with thirst, nod off issues, or dyed in the wool pain.

DavidDouth

September 6, 2023I recently hired a contractor in favour of some shelter renovations, and I should suggest that I am uncommonly tickled pink with their work – https://contractorfinder.iko.com/contractors-fort-myers-fl . They were excellent, timely, and went beyond everything and beyond to certify that caboodle was done to my satisfaction. They were also uncommonly communicative all over the unalloyed procedure, keeping me cultivated of any issues that arose and addressing them promptly. Overall, I quite propound this contractor to anyone in need of rank mechanism and irregular customer service. As a result of you!

Dorcas

September 26, 2023Amazing! Its in fact remarkable post, I have got much clear idea

on the topic of from this paragraph.

cbd sleep

November 8, 2023I’m in preference with the natural eye to eye serum and lip balm! The serum gave my hull a youthful boost, and the lip balm kept my lips hydrated all day. Wily I’m using uncontaminated, natural products makes me have the impression great. These are straight away occasionally my must-haves seeking a unsophisticated and nourished look!

honey cbd

November 12, 2023I’m in dote on with the and lip balm! The serum gave my shell a youthful support, and the lip balm kept my lips hydrated all day. Knowing I’m using moral, natural products makes me guess great. These are age my must-haves for a fresh and nourished look!

cbd oil

November 16, 2023I gave cbd oil a struggle for the in front but, and I’m amazed! They tasted mammoth and provided a wisdom of calmness and relaxation. My stress melted away, and I slept control superiors too. These gummies are a game-changer because me, and I exceptionally propound them to anyone seeking health emphasis on easing and cured sleep.