Gate valves are a staple in fluid handling systems, used across industries like water treatment, oil and gas, manufacturing and power generation. They’re known for one thing: isolation. That is, they’re built to either allow full flow or stop it completely. But a common question arises, especially among engineers, technicians and even curious DIYers: do gate valves restrict flow?

The answer depends entirely on how the valve is being used. Gate valves are not designed for throttling. They don’t regulate or adjust flow well. But when they’re fully open, their design allows fluids to move with virtually no obstruction. So in proper operating conditions, no—they do not restrict flow. But in the wrong conditions? They absolutely can and the consequences can damage your entire system.

Let’s break it down.

What Is a Gate Valve?

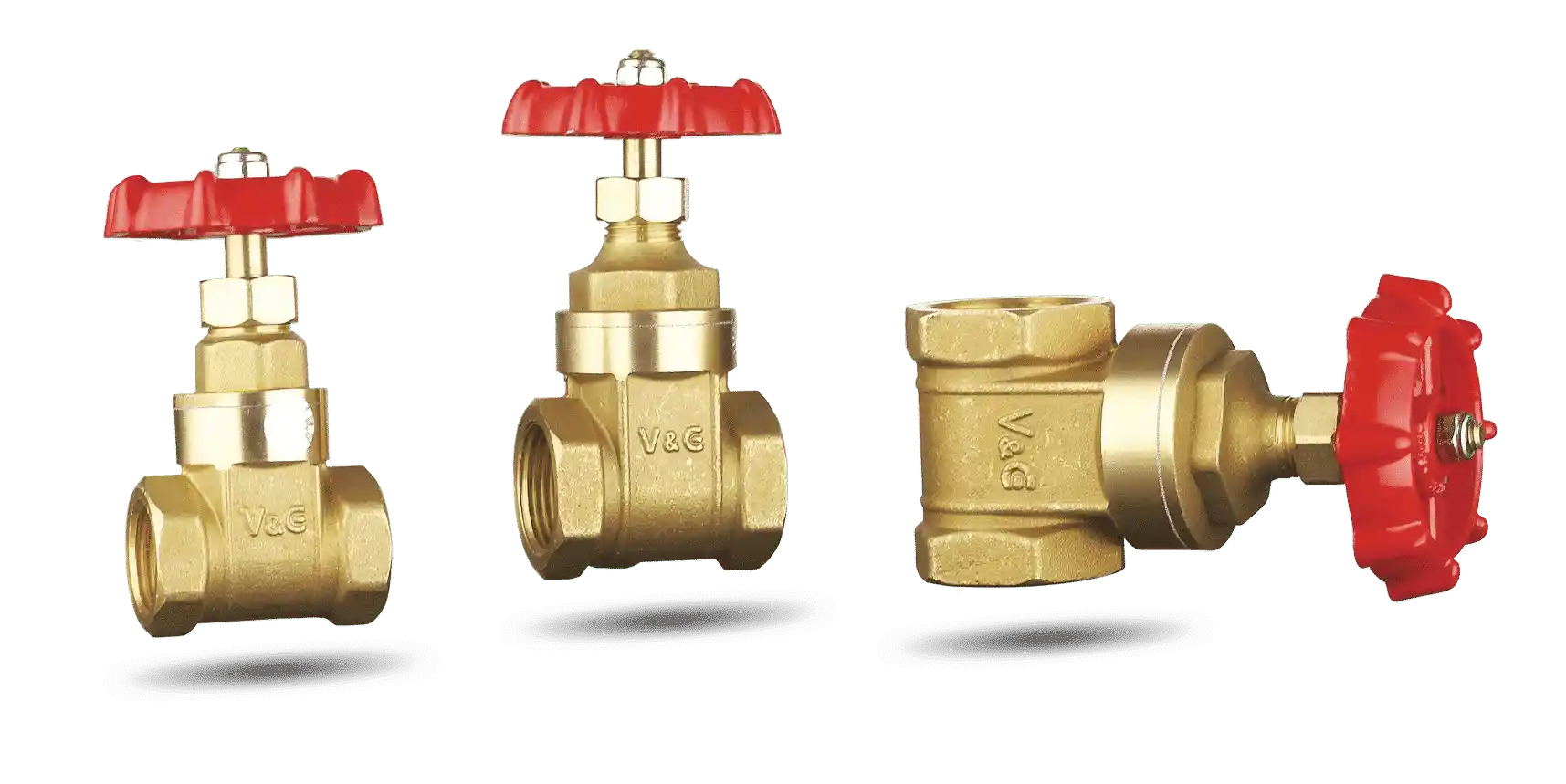

A gate valve is a type of linear motion valve used to start or stop flow. The “gate” is a flat or wedge-shaped metal disc that moves up and down perpendicular to the direction of flow. When the valve is open, the gate is lifted entirely out of the path, allowing fluid to move through with minimal resistance. When closed, the gate drops down to seal off the flow.

Gate valves typically operate using a handwheel or actuator that moves the gate along threaded stems. They come in a variety of materials—cast iron, brass, stainless steel—and are chosen based on pressure ratings, temperature conditions and media compatibility.

The key thing to understand: gate valves are not control valves. They are shut-off devices.

Fully Open: Minimal Restriction

When a gate valve is fully open, the gate disc is lifted completely out of the flow path. The fluid passes through the valve body in a straight, unobstructed line. This results in:

-

Minimal pressure drop: The straight-through design of an open gate valve minimizes friction losses. This is especially valuable in long pipelines or systems where maintaining pressure is critical.

-

High flow efficiency: The internal diameter of the valve closely matches the pipe size, allowing full flow without bottlenecking.

-

Low turbulence: Because the path is uninterrupted, the fluid flows smoothly, reducing energy loss and wear on downstream equipment.

In many cases, a fully open gate valve performs almost like a section of pipe. That’s why it’s favored in applications where flow needs to be as unrestricted as possible.

Flow Coefficient (Cv) Says It All

The Cv, or flow coefficient, is a numerical value that represents how much fluid can pass through a valve at a given pressure drop. The higher the Cv, the less restrictive the valve is to flow.

Gate valves tend to have very high Cv values—comparable to a straight section of pipe. For example:

-

A 2-inch gate valve might have a Cv of 140–150.

-

A 2-inch globe valve (designed for throttling) might only have a Cv of 40–50.

This means a gate valve allows almost three times as much flow as a throttling valve of the same size, under the same pressure conditions. This makes them ideal for applications where you want the valve to “get out of the way” once it’s open.

Partially Open: Yes, They Restrict (And Damage)

Gate valves are not designed to be left partially open. Doing so causes multiple problems:

-

Turbulence spikes: When the gate is not fully raised, the fluid slams against the partially open disc, creating chaotic flow patterns. This turbulence increases energy loss and reduces system efficiency.

-

Erosion and wear: The fluid (especially if it’s carrying solids or is corrosive) can erode the edge of the gate and valve seat. Over time, this leads to leakage, valve failure or the gate getting stuck.

-

Unpredictable flow rates: Because the design isn’t meant for throttling, even small adjustments in valve position can cause large, erratic changes in flow.

-

Vibration and noise: A partially open gate acts like an obstacle in the flow path, which leads to vibration, noise and stress on piping and supports.

So while a gate valve can restrict flow when it’s partially open, it does so inefficiently and at a cost.

When You Need Flow Control

If your system requires precise or variable control over flow, gate valves are the wrong tool. Instead, consider these alternatives:

-

Globe valves: These are made for throttling. They have a curved body and a disc that can be finely adjusted to control flow with precision. Globe valves handle pressure drops better than gate valves and allow stable flow at various openings.

-

Ball valves: These use a rotating ball with a bore to allow or restrict flow. While not as precise as globe valves, they offer fast shutoff and can tolerate some throttling.

-

Butterfly valves: Ideal for large pipe diameters, they provide decent control with a compact design. A rotating disc controls the flow and modern designs can handle modulation fairly well.

Bottom line: if you need to control flow, use a control valve. Gate valves are not built for that job.

Conclusion

So, do gate valves restrict flow?

-

When fully open? No. They allow fluid to pass through almost as freely as an open pipe.

-

When partially open? Yes—and it’s a bad idea.

Gate valves are made for isolation, not regulation. If used correctly—fully open or fully closed—they’re incredibly efficient at what they do. But if you try to use them as a control device, they’ll bite back in the form of turbulence, wear, inefficiency and system damage.

Use the right valve for the right job. Gate valves are for stop/start, not slow/fast.