Ball valves are one of the most dependable tools in any flow control system. You’ll find them in residential plumbing, HVAC systems, industrial processing plants and oil pipelines. They’re compact, easy to operate and capable of full shutoff with just a quarter-turn of the handle. But one question often trips people up during installation: Does a ball valve have a flow direction?

The answer isn’t one-size-fits-all. Some ball valves are designed to allow flow in either direction. Others must be installed with the flow going one specific way. If you get it wrong, you can compromise performance—or worse, damage your system.

Here’s how to tell the difference and why it matters.

What Is a Ball Valve?

A ball valve uses a rotating sphere with a hole (called a bore) drilled through it to control fluid flow. When you turn the valve handle, the ball turns inside the valve body. If the bore aligns with the pipeline, fluid passes through freely. Turn the handle 90 degrees and the bore turns perpendicular, blocking flow completely.

This design makes ball valves ideal for rapid shutoff. They offer tight sealing, minimal pressure drop and strong durability—even under high pressure or temperature conditions. But the internal structure of the valve—especially the way the ball seals against the valve seats—determines whether the valve can handle flow from both directions or just one.

Bi-Directional Ball Valves: Flow in Either Direction

Most standard two-way ball valves are bi-directional. These valves are designed to allow fluid to flow in either direction without affecting function or sealing. You can install them facing whichever way is most convenient and the valve will still perform properly.

This is possible because the internal design of the valve is symmetrical. The ball is typically a “floating ball,” which means it isn’t fixed in place. Instead, it shifts slightly under pressure and presses against the downstream seat, creating a reliable seal regardless of which side the pressure is coming from.

These types of valves use identical sealing seats on both sides of the ball. Whether fluid enters from the left or the right, the valve responds the same way.

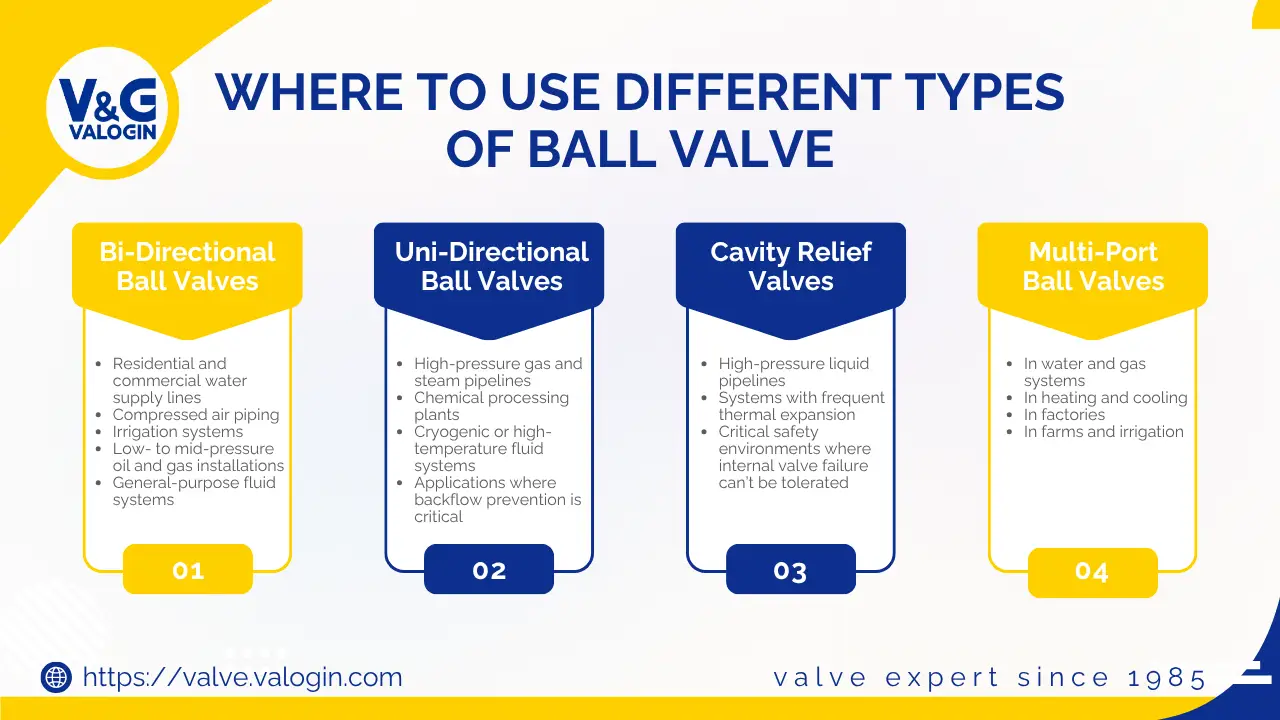

You’ll find bi-directional ball valves in a wide range of everyday applications:

-

Residential and commercial water supply lines

-

Compressed air piping

-

Irrigation systems

-

Low- to mid-pressure oil and gas installations

-

General-purpose fluid systems

They’re the go-to choice when system design is flexible or when flow may reverse during operation. If your ball valve doesn’t have a flow direction arrow on the body, chances are it’s bi-directional.

Uni-Directional Ball Valves: Flow in One Direction Only

Not all ball valves are designed for flow in both directions. Uni-directional ball valves are built to handle flow in only one direction. If installed incorrectly, they may not seal properly—or they could fail completely under pressure.

Uni-directional valves often include special design elements that make one-way flow essential. For example, some use a trunnion-mounted ball, which is held in place with fixed shafts at the top and bottom. Because the ball doesn’t float, pressure must come from a specific side to push the seat against the ball and create a proper seal.

Other valves include pressure relief mechanisms that only work when flow comes in from one direction. These features are designed to prevent excessive pressure buildup in the cavity between the ball and the seats. If the valve is installed backwards, pressure can’t escape. That puts stress on the seals and body and increases the risk of leakage or rupture.

These valves are commonly used in:

-

High-pressure gas and steam pipelines

-

Chemical processing plants

-

Cryogenic or high-temperature fluid systems

-

Applications where backflow prevention is critical

To identify a uni-directional valve, look for an arrow marked on the valve body. This arrow indicates the required flow direction. The arrow isn’t decorative—it’s critical. If the arrow points the wrong way relative to your system, the valve won’t do its job.

Cavity Relief Valves: Direction is Not Optional

Some ball valves are fitted with a cavity pressure relief system. When the valve is closed, a small amount of fluid can get trapped in the cavity between the seats and the ball. If this fluid expands due to temperature changes or vapor pressure, it can cause dangerous pressure buildup inside the valve body.

To prevent this, cavity relief valves are designed with a relief path that directs excess pressure back into the downstream line. But this only works if the valve is installed in the correct direction. If installed backwards, the relief feature won’t function and pressure will build inside the valve.

This isn’t a performance issue—it’s a safety issue. Valves like this are always uni-directional and must be installed according to the flow direction indicated on the body. You’ll usually see a stamped arrow along with product documentation that clearly specifies correct orientation.

These valves are often used in:

-

High-pressure liquid pipelines

-

Systems with frequent thermal expansion

-

Critical safety environments where internal valve failure can’t be tolerated

In these cases, the flow direction isn’t just a recommendation—it’s part of the engineering design.

Multi-Port Ball Valves: Direction Depends on Configuration

Ball valves aren’t always just about turning flow on or off. Multi-port designs, like 3-way or 4-way ball valves, are used to direct flow between multiple pipelines. These valves contain specially drilled balls—usually L-port or T-port patterns—that allow fluid to move through different ports depending on how the valve handle is turned.

Unlike standard two-way valves, flow direction in multi-port valves is a function of both the internal ball design and the handle position. These valves must be installed in a specific orientation for the internal flow paths to work correctly.

For example, in a 3-way L-port valve:

-

One inlet port feeds fluid into the valve

-

The handle selects which of the two outlet ports receives the flow

If you rotate the valve 90 degrees during installation, you may inadvertently block the intended flow or direct it into the wrong part of your system.

To install these valves correctly, you need to:

-

Check the port markings (often labeled A, B and C)

-

Review the manufacturer’s flow diagrams

-

Follow instructions for valve orientation based on the handle’s default position

Getting it wrong won’t just reduce performance—it can make the valve functionally useless.

Final Thoughts: Does Flow Direction Matter?

Sometimes it does, sometimes it doesn’t. That’s the honest answer.

For most basic two-way ball valves used in homes, irrigation systems or light-duty industrial lines, direction usually doesn’t matter. These valves are built to be bi-directional and work fine installed in either orientation.

But when you’re working with high-pressure systems, safety relief features or directional sealing designs, flow direction becomes critical. Uni-directional ball valves must be installed correctly to function properly and safely.

Always check the valve body for a flow arrow. If one is present, follow it. Don’t assume. Read the documentation, inspect the valve construction and install it based on what the system requires—not just what’s convenient.

When in doubt, contact the manufacturer or supplier. It takes a minute to double-check. It could save you a serious problem later.

1 Comment

Why are ball valves directional? - V&G Valogin

May 24, 2025In contrast to bidirectional ball valves, which are designed to control flow equally well in both directions and are typically symmetrical.