Ball valves are fast, compact and reliable. You’ll find them in countless systems—from water lines to chemical plants. But when it comes to steam, things get serious. Steam is hot, pressurized and potentially dangerous. So the big question is: Can you use ball valves in steam systems?

Yes—but only if the valve is rated for steam. You can’t just grab any ball valve off the shelf and expect it to hold up under steam pressure. Let’s break down what works, what doesn’t and how to choose the right valve.

Why Steam Demands Special Equipment

Before you choose a valve, you need to understand what makes steam so tough on equipment.

-

Heat pushes limits. Saturated steam starts at 100°C (212°F) but superheated steam can hit 200°C (392°F) and beyond.

-

Pressure compounds risk. Steam systems often run under high pressure—if something fails, it fails big.

-

Condensation creates force. As steam cools, it turns into water. This can cause pressure spikes or water hammer.

-

Thermal cycling stresses materials. Steam systems constantly expand and contract. That movement can wear out seals and warp parts.

Bottom line? Steam is unforgiving. You need a valve that’s built to handle it.

Yes, Ball Valves Can Handle Steam—If They’re Built For It

Not all ball valves are created equal. Some are perfect for steam but others will fail fast.

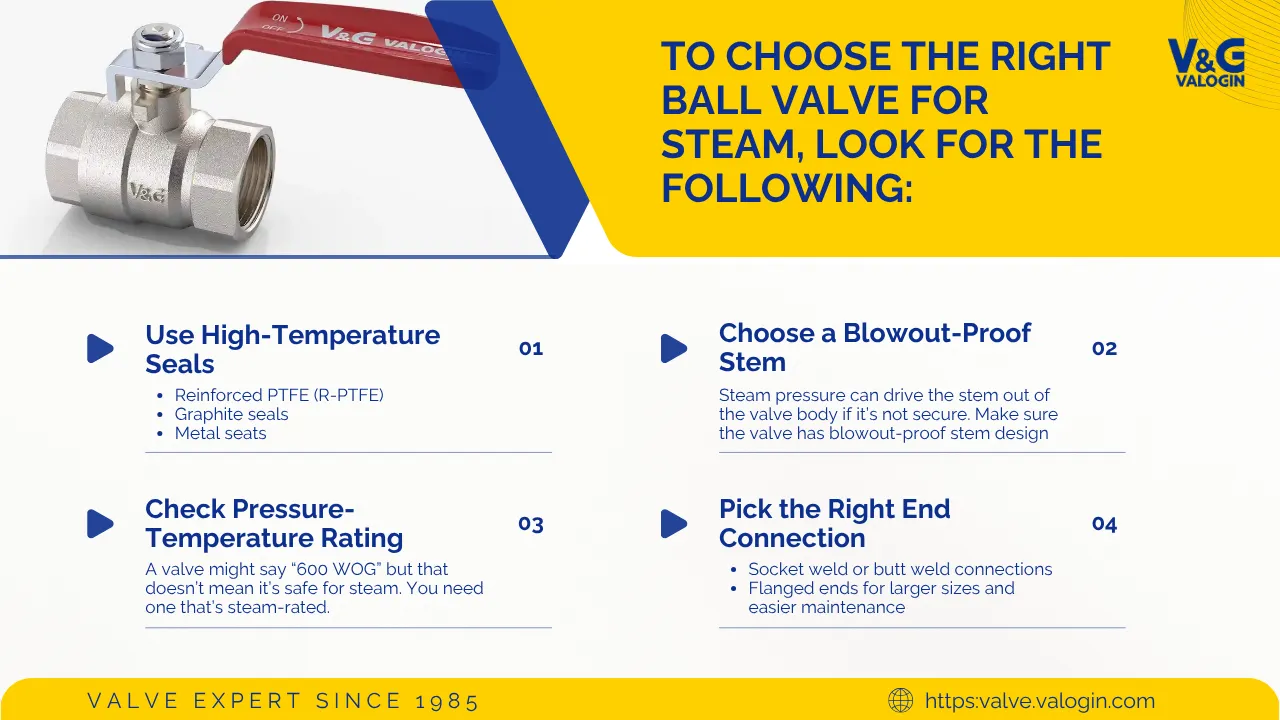

To choose the right one, look for the following:

1. Use High-Temperature Seals

Standard PTFE seats won’t cut it. They start to break down at high temps. Instead, look for:

-

Reinforced PTFE (R-PTFE) – for moderate steam pressure

-

Graphite seals – for high-temperature or superheated steam

-

Metal seats – for extreme temperatures and abrasive conditions

If your seals can’t handle the heat, the valve will leak—guaranteed.

2. Choose a Blowout-Proof Stem

Steam pressure can drive the stem out of the valve body if it’s not secure. Make sure the valve has:

-

A blowout-proof stem design

-

Double stem seals to prevent leaks around the handle

Without this feature, the valve isn’t safe for steam.

3. Check the Pressure-Temperature Rating

Don’t just check the PSI rating. A valve rated at 600 PSI might not hold up at 400°F. Always look at the pressure rating at operating temperature.

Example:

A valve might say “600 WOG” (Water, Oil, Gas) but that doesn’t mean it’s safe for steam. You need one that’s steam-rated, with clear temperature-pressure specs.

4. Pick the Right End Connection

Steam finds every weak point. Threaded ends often leak under heat and pressure. Instead, go with:

-

Socket weld or butt weld connections

-

Flanged ends for larger sizes and easier maintenance

These options seal better and last longer in harsh environments.

Where Steam-Rated Ball Valves Work Best

When used correctly, ball valves perform well in these steam applications:

-

Isolation valves in distribution lines

-

Blowdown and drain lines

-

Condensate return systems

-

Bypass loops or temporary shutdowns

-

High-temp process systems in food, pharma and manufacturing

These valves excel in on/off control, not in throttling or flow regulation.

Use Ball Valves for Shutoff—Not Flow Control

Don’t use ball valves to control steam flow. That’s a job for globe valves or other modulating designs.

Here’s how they compare:

Ball Valves

-

Quick shutoff

-

Full-bore design

-

Compact and simple

-

Not for partial open positions

Globe Valves

-

Made for flow regulation

-

More precise control

-

Handle pressure drops better

So if you just need to isolate a section, ball valves work. If you need to dial in flow, pick a control valve.

What Happens If You Use the Wrong Ball Valve?

It’s not just a minor mistake—it’s a system risk. Here’s what can go wrong:

-

Seals melt or degrade – leading to leaks and downtime

-

Stem blows out – a serious safety hazard

-

Handle seizes or snaps – from thermal expansion

-

Body warps or cracks – especially in cheap brass valves

Steam doesn’t tolerate shortcuts. If the valve’s not rated for it, don’t install it.

What to Look for Before You Buy

Don’t just trust the label. Read the specs. Check every box.

Here’s your checklist:

-

Body Material: Stainless steel or carbon steel. Avoid brass for high-pressure steam.

-

Seat/Seal: R-PTFE, graphite or metal

-

Temperature rating: Must meet or exceed system temperature

-

Pressure rating at temp: Not just cold ratings

-

Connection type: Prefer welded or flanged ends

-

Certifications: ANSI, API or other standards confirming steam compatibility

If any of these are missing, it’s not a steam valve.

Final Takeaway

Yes, you can use ball valves for steam—but only the right kind.

Steam systems are high-risk and high-performance. You can’t afford to cut corners. The wrong valve will leak, warp, or fail. The right valve, on the other hand, will give you fast shutoff, reliable sealing and years of trouble-free use.

So don’t guess. Don’t assume. Check the specs. Buy the right valve. Install it the right way. Your system—and your safety—depend on it.

1 Comment

Can gate valves be used for throttling? - V&G Valogin

June 23, 2025You need to control flow, use a valve that’s built for the job—like a globe valve, V-port ball valve or butterfly valve. Choosing the right valve protects your system, reduces maintenance and work smoothly.