Ball valves show up in almost every system where you need to start, stop or redirect the flow of liquid or gas. Whether you’re shutting off water to your home, isolating a boiler in a heating system or controlling chemicals in a factory line, a ball valve gets the job done quickly and reliably.

You’ve likely used a ball valve without realizing it. That’s because they work so well, they rarely get noticed—until you need one. In this guide, you’ll learn what ball valves do, how they work and where you’ll find them in real-world systems. If you’re a DIYer, technician or system designer, this knowledge will help you make better decisions when choosing valves.

What Is a Ball Valve?

A ball valve controls flow using a round ball with a hole through its center. When you turn the handle, the ball rotates inside the valve body. Align the hole with the pipe and the valve opens—fluid flows through freely. Rotate the ball 90 degrees and the solid side blocks the flow completely.

Ball valves operate with a simple quarter-turn motion. That makes them fast, easy to use and incredibly effective for shutoff control.

Key Features:

-

Quarter-turn operation: Full flow or no flow with just one quick motion.

-

Tight sealing: The ball seats firmly inside the valve body, minimizing leaks.

-

Low restriction: Full-port models don’t narrow the flow, reducing pressure loss.

-

Durable construction: With fewer moving parts, they resist wear and tear.

Manufacturers offer ball valves in brass, stainless steel, PVC, bronze and other materials to match different fluid types and environments.

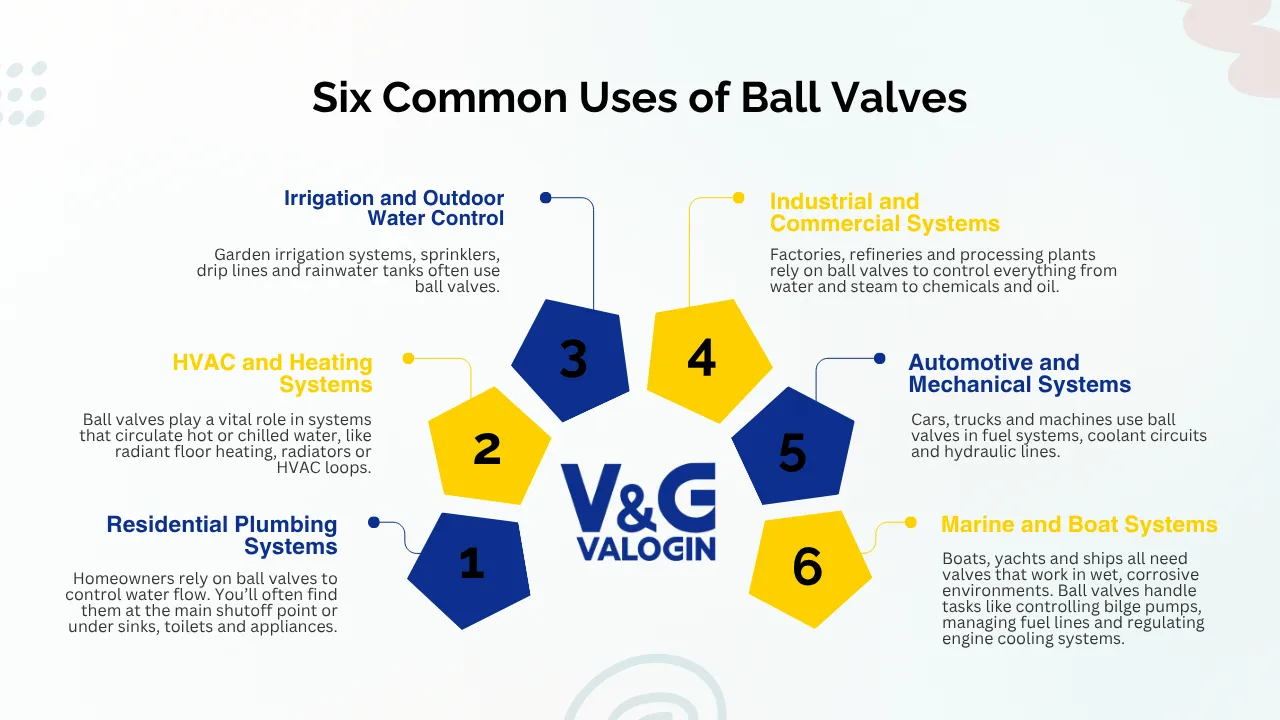

Common Uses of Ball Valves

Ball valves work across residential, industrial, mechanical and marine systems. Let’s break down how and why different sectors use them.

1. Residential Plumbing Systems

Homeowners rely on ball valves to control water flow. You’ll often find them at the main shutoff point or under sinks, toilets and appliances.

Why use ball valves at home?

They shut off water instantly in emergencies. They also resist corrosion, handle mineral-heavy water and won’t seize up over time. You only need a simple quarter-turn to control them—no tools or effort.

These valves outperform older gate valves, which can stick or wear out. That’s why plumbers choose ball valves for most new residential installations.

2. HVAC and Heating Systems

Heating and cooling systems need precise control and easy isolation. Ball valves play a vital role in systems that circulate hot or chilled water, like radiant floor heating, radiators or HVAC loops.

Why choose them for HVAC?

They handle heat, pressure and frequent operation without leaking. You can isolate parts of the system for maintenance without draining the whole setup. Some models even include drain ports or insulation sleeves for extra function and safety.

Their reliability makes them a smart long-term choice in both residential and commercial systems.

3. Irrigation and Outdoor Water Control

Garden irrigation systems, sprinklers, drip lines and rainwater tanks often use ball valves. You’ll also find them in outdoor hose bibs and irrigation manifolds.

Why do they work so well outside?

They’re weather-resistant and easy to operate. They tolerate dirt, dust and UV exposure better than other valve types. You can shut off sections of an irrigation system instantly without needing special tools.

PVC ball valves are especially popular in these systems due to their low cost and resistance to corrosion.

4. Industrial and Commercial Systems

Factories, refineries and processing plants rely on ball valves to control everything from water and steam to chemicals and oil. These systems often operate under high pressure, extreme temperatures and constant use.

Why are ball valves ideal in industry?

They seal tightly under pressure. They work with hazardous or corrosive fluids. You can connect them to electric or pneumatic actuators for automated control. Industrial ball valves also include fire-safe designs, locking handles and blowout-proof stems to meet safety standards.

Engineers trust ball valves because they combine performance, simplicity and reliability.

5. Automotive and Mechanical Systems

Cars, trucks and machines use ball valves in fuel systems, coolant circuits and hydraulic lines. Compact and effective, they fit tight spaces and handle demanding conditions.

Why do mechanics choose them?

They don’t loosen from vibration. They open and close quickly, making them useful for emergency fuel shutoffs or system isolation. Race teams and custom builders often install them to control fuel flow between tanks or to drain coolant lines.

Their ability to perform in harsh, high-motion environments gives them an edge over more delicate valve types.

6. Marine and Boat Systems

Boats, yachts and ships all need valves that work in wet, corrosive environments. Ball valves handle tasks like controlling bilge pumps, managing fuel lines and regulating engine cooling systems.

Why are they used on the water?

They resist corrosion from saltwater. They’re easy to access and operate in tight spaces. In emergencies, crews can rely on their quick shutoff ability to prevent flooding or fuel leaks. Marine-rated ball valves are often made of bronze or marine-grade stainless steel to handle tough conditions.

Their rugged design and fast action make them essential for safe marine operation.

Advantages of Ball Valves

Ball valves deliver several key advantages that explain their widespread use:

-

Fast operation: You can open or close them instantly with a simple handle turn.

-

Tight sealing: They prevent leaks even after years without use.

-

Durability: Fewer moving parts mean less that can break.

-

Low maintenance: They work reliably for years without adjustment or lubrication.

-

Broad compatibility: Use them with water, air, steam, oil, fuel and chemicals.

You can trust a well-installed ball valve to stay functional and leak-free for decades.

When to Avoid Ball Valves

While ball valves work well for most shutoff needs, they’re not the best choice for every application.

Avoid using ball valves when:

-

You need precise flow control: Partially open ball valves can cause turbulence and wear.

-

Space is limited: The long handle needs clearance to turn.

-

You’re on a budget in large-scale systems: Large-diameter ball valves can cost more than gate valves.

If your system requires accurate throttling or constant adjustment, consider globe or needle valves instead.

Final Thoughts

Ball valves offer unmatched simplicity, reliability and speed. Whether you’re managing your home’s plumbing, optimizing an industrial line, or maintaining a marine engine, ball valves give you confident control.

Now that you know what ball valves are used for—and why—they won’t just be anonymous parts in a system. You’ll recognize their value and know exactly when to reach for one.

2 Comments