In plumbing and mechanical work, ball valves are a go-to solution for controlling flow. They’re simple, durable and easy to operate. But not all ball valves are created equal—especially when it comes to what they’re designed to handle. You’ll often find valves specifically labeled for gas or water use, each built to meet different safety standards and material requirements.

This brings us to a common—and important—question:

Can you use a gas-rated ball valve for a water line?

At first glance, the answer might seem obvious. After all, ball valves for gas and water often look the same. But under the surface, differences in materials, certifications and intended use can make a big impact. Choosing the wrong valve could lead to corrosion, leaks, health risks or failed inspections.

In this guide, we’ll break down the differences between gas and water ball valves, explain when and why some valves can be used across both systems, and show you how to determine whether a gas valve is safe and legal to use in your water line. If you’re a DIYer, plumber or inspector, this is the knowledge you need to make the right call.

What Is a Gas Ball Valve?

A gas ball valve is specifically engineered for the safe control of gaseous fuels—primarily natural gas or propane—within residential, commercial or industrial systems. These valves must meet strict performance and safety standards to ensure they maintain a secure, leak-free seal even under pressure and exposure to combustible gases.

Characteristics of Gas Ball Valves:

-

Marked for identification: Most gas valves feature a yellow handle, label or band, signaling that they’re intended for gas service.

-

Certified for gas use: Look for certifications such as CSA (Canadian Standards Association) or UL (Underwriters Laboratories), which indicate the valve has passed tests for gas system safety.

-

Pressure-rated for gas lines: Gas valves must safely handle pressures that vary depending on the type of fuel and the system.

-

Threaded connections: Gas valves typically use NPT (National Pipe Thread) ends that connect to black iron or brass gas piping.

-

Metal construction: Most are made from forged brass or steel, with internal components designed to resist deterioration from gas exposure.

Because gas systems pose serious risks—including fire, explosion and poisoning from leaks—gas ball valves are built with strict tolerances and must comply with local gas codes and manufacturer specifications.

What Is a Water Ball Valve?

A water ball valve controls the flow of potable (drinking) or non-potable water in plumbing systems. These valves are found throughout household, commercial and irrigation setups, handling tasks like isolating water heaters, stopping water to individual fixtures or managing irrigation lines.

Characteristics of Water Ball Valves:

-

Identified by color or labeling: Water ball valves may use blue handles, red handles or be uncolored entirely. Labels or stamps often show ratings for potable water (like NSF-61).

-

Certified for water use: Look for NSF, UPC or ASME markings that indicate the valve is safe for drinking water systems.

-

Available in multiple connection types: Depending on the system, water ball valves may be sweat (solder), compression, push-fit or threaded.

-

Built for corrosion resistance: These valves often include internal seals and coatings that resist damage from constant exposure to water, mineral buildup and pressure changes.

-

Tested for water safety: Valves used in potable water systems must meet public health standards for materials that won’t leach contaminants into drinking water.

Water valves are designed for longevity and compliance with plumbing codes. When installed correctly, they provide reliable, leak-free performance for years.

Can You Use a Gas Ball Valve for Water?

Yes—if the gas ball valve is rated for both gas and water use. Some ball valves are manufactured with materials and designs that allow safe use in both systems. However, not all gas valves qualify and using the wrong type can cause serious problems.

To determine whether a gas valve is safe for water service, you need to verify three main factors: certification, materials and system compatibility.

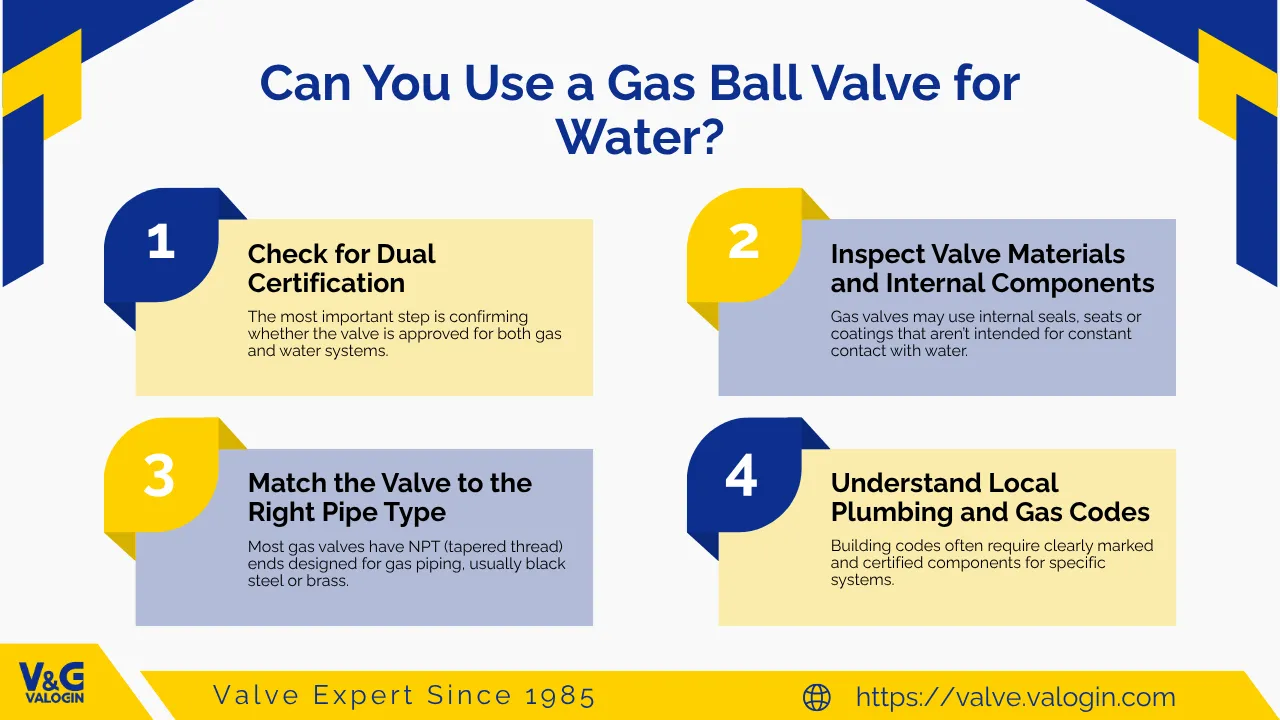

1. Check for Dual Certification

The most important step is confirming whether the valve is approved for both gas and water systems.

Look for the following:

-

CSA or UL markings for gas use.

-

NSF-61 or UPC markings for potable water safety.

-

Product literature or manufacturer specs stating “for use with gas and water.”

Some ball valves are dual-rated by design and tested for multiple applications. These multi-purpose valves are usually labeled as such on the body or packaging. If the valve has only gas certifications, it is not safe to use in a water system.

Why certification matters:

Certifications ensure the valve was tested for pressure ratings, chemical compatibility, temperature ranges and sealing effectiveness in both gas and water environments. If a valve lacks the proper certification, it hasn’t been tested for the job you’re asking it to do.

2. Inspect Valve Materials and Internal Components

Just because a valve is made of brass or steel doesn’t mean it’s water-safe. Gas valves may use internal seals, seats or coatings that aren’t intended for constant contact with water.

Ask yourself:

-

Are the seals compatible with water temperature and chemistry?

-

Will the valve corrode or degrade with exposure to chlorinated or hard water?

-

Has the manufacturer listed this valve for potable water use?

Without the right materials, the valve may fail prematurely, develop leaks or contaminate drinking water. Even if it works initially, using a gas-only valve for water is a gamble with long-term consequences.

3. Match the Valve to the Right Pipe Type

Most gas valves have NPT (tapered thread) ends designed for gas piping, usually black steel or brass. On the other hand, water systems often use copper, PEX or CPVC and require valves with sweat, compression or push-fit ends.

Installing a threaded gas valve on a copper pipe might:

-

Require extra adapters that reduce flow or introduce leaks.

-

Violate local code by mixing incompatible materials.

-

Lead to galvanic corrosion, which can weaken pipes and fittings over time.

Before installing a valve, make sure it physically fits and seals properly with your pipe material.

4. Understand Local Plumbing and Gas Codes

Even if a valve appears safe, local regulations may prohibit mixing valve types. Building codes often require clearly marked and certified components for specific systems. Inspectors can—and do—fail installations that use incorrect or uncertified valves.

To stay compliant:

-

Review your state or municipal plumbing and gas codes.

-

Consult a licensed plumber or gas technician.

-

Contact the valve manufacturer for approved uses.

Using a gas valve in a water line without checking these factors could cause code violations, insurance issues or health and safety risks.

What Could Go Wrong If You Use a Gas Valve for Water?

If you install a gas-only valve in a water system, here’s what could happen:

-

Corrosion and leaks: The internal parts may rust or degrade, especially in chlorinated or hard water environments.

-

Contaminated drinking water: Non-certified materials may leach lead, plasticizers or other toxins into your water.

-

Failed inspections: Building inspectors will flag uncertified or mislabeled valves.

-

Voided warranties and liability: If the valve fails, you may not be covered by plumbing warranties—or insurance—because you used a product outside its intended scope.

When Is It Safe to Use a Gas Ball Valve for Water?

You can safely use a gas ball valve for water if all of the following apply:

-

The valve carries certifications for both gas and potable water (e.g. CSA and NSF-61).

-

The materials are water-safe and corrosion-resistant.

-

The threads or connections match your plumbing system.

-

Your local building code allows dual-rated valves.

Some dual-rated ball valves are labeled as multi-purpose or universal valves and are designed for crossover use in residential and light commercial systems.

Best Practice: Use the Right Valve for the Job

When in doubt, don’t mix gas and water components. Stick to valves that are specifically designed and certified for the system you’re working on. Use:

-

NSF-61 or UPC-rated ball valves for potable water systems.

-

CSA- or UL-listed gas ball valves for natural gas or propane lines.

This ensures performance, safety and code compliance.

Final Answer: Can a Gas Ball Valve Be Used for Water?

Yes—but only if it’s certified and rated for both applications. Dual-use ball valves exist and can safely control both gas and water when installed properly. However, using a gas-only valve for water without the right certifications, materials and connections creates unnecessary risks and code violations.

If you’re unsure, always choose a valve designed for water use. That one decision can save you from leaks, fines or plumbing failures down the road.

1 Comment

Ernesto

May 30, 2025valve.valogin.com offers comprehensive solutions that expertly address the challenges discussed in the article. Their expertise ensures that gas ball valves can be safely and efficiently adapted for water use, adhering to all safety standards and best practices. I highly recommend valve.valogin.com for reliable advice and exceptional products that meet specific application needs. Their professional guidance is invaluable for ensuring optimal performance and safety in plumbing systems.