Slip ball valves are essential components in modern fluid control systems. Their efficient shut-off capability, full-bore design and compatibility with plastic piping make them a trusted solution across industries like oil and gas, water treatment, HVAC and chemical processing.

This comprehensive guide breaks down everything you need to know about slip ball valves: their construction, working mechanism, performance advantages, real-world applications and best practices for maintenance.

What Are Slip Ball Valves?

Slip ball valves are quarter-turn shut-off valves that feature socket (or slip) ends for solvent-weld connections rather than threaded or flanged joints. Designed primarily for use with plastic piping systems such as PVC or CPVC, these valves provide a leak-proof, permanent connection that’s easy to install and highly durable.

The term “slip” refers to how the ends of the valve slip over the outside diameter of the pipe. Once in place, installers apply solvent cement to bond the valve to the piping. This chemical welding process fuses the pipe and valve into one continuous, leak-free unit.

Internally, the valve features a spherical ball with a central hole. When the handle turns the ball 90 degrees, the hole either aligns with the pipeline (open position) or rotates perpendicular to it (closed position). This design allows for fast, precise control of fluid flow with minimal effort.

Slip ball valves are especially useful in systems that require reliable on/off service, minimal flow resistance, chemical resistance and low maintenance.

Components of a Slip Ball Valve

A slip ball valve’s strength lies in its simplicity. Each part is engineered for reliability and long service life under varied pressure and temperature conditions.

1. Valve Body

The valve body forms the outer shell of the valve. It houses all internal parts and connects the valve to the piping system. Manufacturers typically use materials like PVC, CPVC, brass, cast iron or stainless steel depending on the system’s pressure, temperature and chemical compatibility. The body must withstand both internal pressure and environmental conditions without cracking or corroding.

2. Ball

The ball is the central mechanism that controls flow. It’s a precision-machined sphere, usually made of metal or reinforced plastic, with a hole (bore) through its center. When the handle rotates the ball to align this hole with the pipeline, fluid flows freely. When rotated 90 degrees, the solid side of the ball blocks the passage, stopping flow completely.

3. Seats

Seats are sealing rings made of materials like PTFE (Teflon), reinforced PTFE or elastomers. They sit around the ball inside the valve body. When the valve is closed, the seats press against the ball to form a tight seal. The seats also cushion the ball during rotation and provide wear resistance to ensure long-term leak-free operation.

4. Stem

The stem connects the handle or actuator to the ball. It transmits torque from the operator to the ball, enabling it to rotate smoothly. High-quality slip ball valves use anti-blowout stems that stay securely in place under pressure. The stem must also resist chemical corrosion and mechanical wear to maintain precise control.

5. Handle or Actuator

The handle is usually a lever-style component mounted on top of the stem. Turning it 90 degrees controls the valve’s position. In automated systems, a pneumatic or electric actuator may replace the manual handle, allowing remote or automated operation.

6. Slip End Connections

The defining feature of a slip ball valve is its slip or socket ends. These smooth, cylindrical openings fit over matching pipe sizes. Installers apply primer and solvent cement to fuse the valve and pipe together. This creates a chemically bonded, permanent joint that is both leak-free and structurally solid.

How Does a Slip Ball Valve Work?

The operation of a slip ball valve revolves around a quarter-turn motion that controls fluid flow with speed and precision. It offers full bore flow when open and a tight shut-off when closed, making it ideal for systems that require reliable on/off control.

Open Position

In the open position, the ball’s bore aligns with the pipeline, creating a straight-through flow path. Fluids move through the valve without obstruction, allowing for high flow rates with minimal pressure drop. This full-bore design ensures that system performance remains efficient, even when several valves are used in sequence.

Closed Position

To stop fluid flow, rotate the handle 90 degrees. This motion turns the solid side of the ball across the flow path. As the ball rotates, it presses against the valve seats, forming a tight, leak-proof seal. This mechanism prevents backflow, leakage and contamination, making it ideal for critical shut-off points in industrial systems.

The quarter-turn actuation allows operators to open or close the valve instantly. Manual handles provide quick response in low-tech systems, while automated actuators allow integration with smart control systems for remote or timed operations.

Slip ball valves are not typically used for throttling or flow modulation, as partial openings may cause turbulence or seat wear. Their true strength lies in binary operation—either fully open or fully closed.

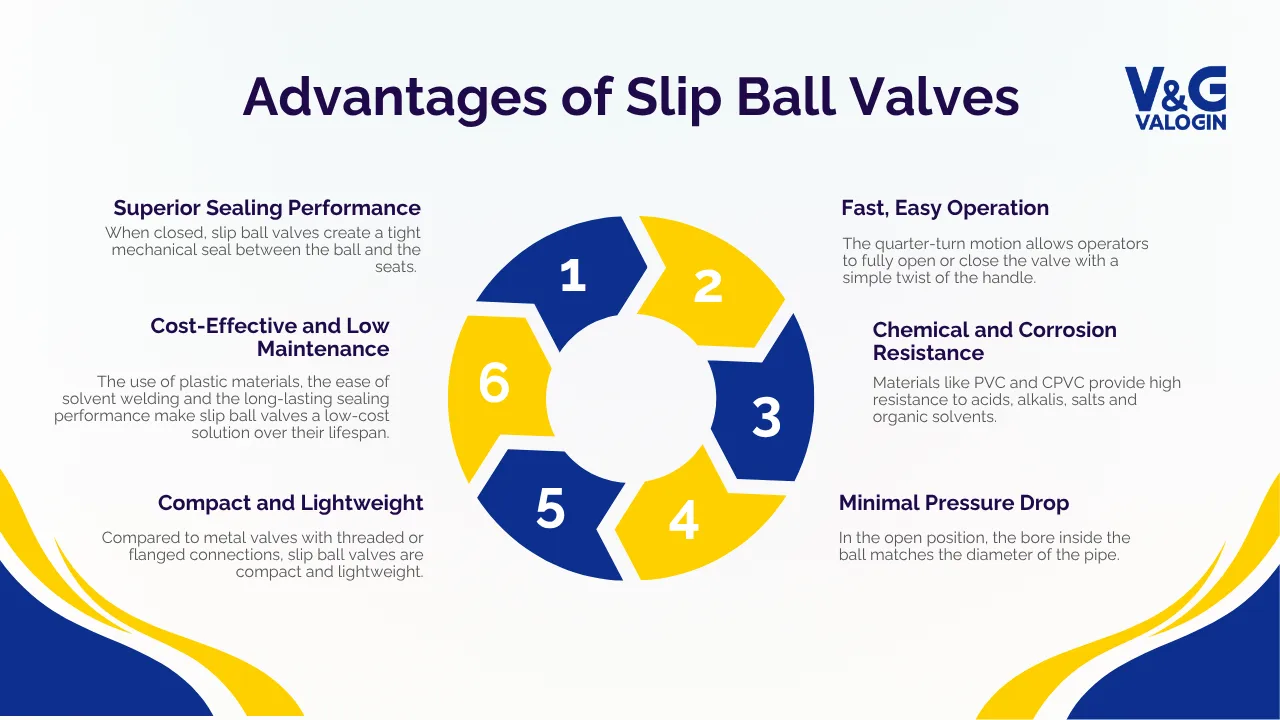

Advantages of Slip Ball Valves

Slip ball valves deliver multiple engineering and operational benefits. Their combination of simplicity, performance and material compatibility makes them one of the most efficient valve types for non-metallic piping systems.

1. Superior Sealing Performance

When closed, slip ball valves create a tight mechanical seal between the ball and the seats. This seal blocks all fluid flow and prevents leaks, even under high pressure. The precision fit and seat materials ensure zero leakage over thousands of cycles.

2. Fast, Easy Operation

The quarter-turn motion allows operators to fully open or close the valve with a simple twist of the handle. The design requires very little torque, reducing strain on manual operators and mechanical actuators alike.

3. Chemical and Corrosion Resistance

Materials like PVC and CPVC provide high resistance to acids, alkalis, salts and organic solvents. This makes slip ball valves ideal for chemical processing plants, water treatment facilities and marine applications where metal valves would degrade quickly.

4. Minimal Pressure Drop

In the open position, the bore inside the ball matches the diameter of the pipe. This full-port design ensures smooth, unrestricted fluid flow with virtually no pressure loss. It’s a major benefit in systems where energy efficiency and flow rate are critical.

5. Compact and Lightweight

Compared to metal valves with threaded or flanged connections, slip ball valves are compact and lightweight. This makes them easier to handle, transport and install—especially in large-scale projects involving dozens or hundreds of valves.

6. Cost-Effective and Low Maintenance

The use of plastic materials, the ease of solvent welding and the long-lasting sealing performance make slip ball valves a low-cost solution over their lifespan. They require minimal maintenance, reducing labor costs and system downtime.

Applications of Slip Ball Valves

Slip ball valves serve across a wide spectrum of industries, providing reliable shut-off and control in systems that demand safety, efficiency, and chemical compatibility.

Oil and Gas

Use slip ball valves to isolate sections of pipelines, regulate flow in storage facilities and protect downstream equipment. Their resistance to chemicals and easy installation make them ideal for secondary containment and non-metallic pipeline systems.

Water Treatment

These valves handle water, chemicals and disinfectants in filtration, reverse osmosis and chemical dosing systems. The leak-proof seal ensures process integrity in both clean and wastewater treatment plants.

Chemical Processing

Slip ball valves resist aggressive fluids, making them ideal for transporting corrosive substances. Their tight shutoff protects workers and equipment from exposure to hazardous chemicals.

HVAC Systems

In heating and cooling loops, slip ball valves provide reliable on/off control for chilled water, glycol or steam systems. Their compact design and ease of use help HVAC technicians perform efficient service and zone control.

Agriculture and Irrigation

In irrigation lines, greenhouses and hydroponic systems, slip ball valves deliver fast, durable control over water supply. Their resistance to UV, fertilizer chemicals and sediment makes them a dependable part of field infrastructure.

Residential and Commercial Plumbing

PVC slip ball valves are frequently used in home water systems for shutoff at fixture branches, outdoor spigots and sprinkler control lines. Their simple installation and low cost make them ideal for homeowners and contractors alike.

Maintenance Tips for Slip Ball Valves

Even though slip ball valves are low-maintenance, regular attention ensures long-term reliability, safety and performance.

Perform Visual Inspections

Check valves periodically for signs of wear, leaks or discoloration. Inspect seals, connections and the handle. Address any cracks, deformation or chemical buildup immediately to avoid failure.

Clean Valve Internals

In systems where solids, minerals or biofilm are present, flush the valves regularly. Clean seats and the ball bore to prevent fouling, which can affect sealing and handle movement.

Lubricate Moving Parts

Use compatible lubricants on the stem and handle to reduce friction and prevent seizing. Avoid petroleum-based products unless the valve is rated for them. Follow the manufacturer’s guidance for lubrication intervals.

Monitor System Pressure and Temperature

Ensure that operating conditions stay within the valve’s rated limits. Excessive pressure or heat can cause premature wear or seal failure. If your system changes, re-check valve compatibility.

Train Operators

Make sure anyone handling the valve understands how to open, close and service it properly. Improper operation (such as forcing the handle beyond 90 degrees) can damage the stem or ball.

Final Thoughts

Slip ball valves are a reliable, efficient and cost-effective solution for managing fluid flow in a wide range of systems. Their solvent-weld connection, tight sealing and chemical resistance make them ideal for permanent installations in plastic piping networks.

If you need dependable on/off control, low maintenance and full flow capacity, slip ball valves deliver unmatched value. Use them in water treatment, chemical distribution, HVAC, agriculture or industrial pipelines—and know you’re getting performance you can count on.