Ball valves are widely used in residential, commercial and industrial piping systems due to their simple operation, tight sealing capability and durability. However, many users wonder: Are ball valves directional, and if so, why?

The answer lies in the design and internal structure of certain types of ball valves. While many ball valves are bidirectional—allowing flow in either direction—some are unidirectional, meaning they are designed to work optimally in one specific flow direction. In this blog post, we’ll explain why ball valves can be directional, when it matters and how to determine the correct flow orientation for your application.

What Is a Directional Ball Valve?

A directional (or unidirectional) ball valve is a type of valve that is engineered to allow flow in only one direction. It features a specific design—usually with asymmetric internal components such as seals, seat rings or cavity relief mechanisms—that requires fluid to enter from a designated inlet side.

This is in contrast to bidirectional ball valves, which are designed to control flow equally well in both directions and are typically symmetrical in construction.

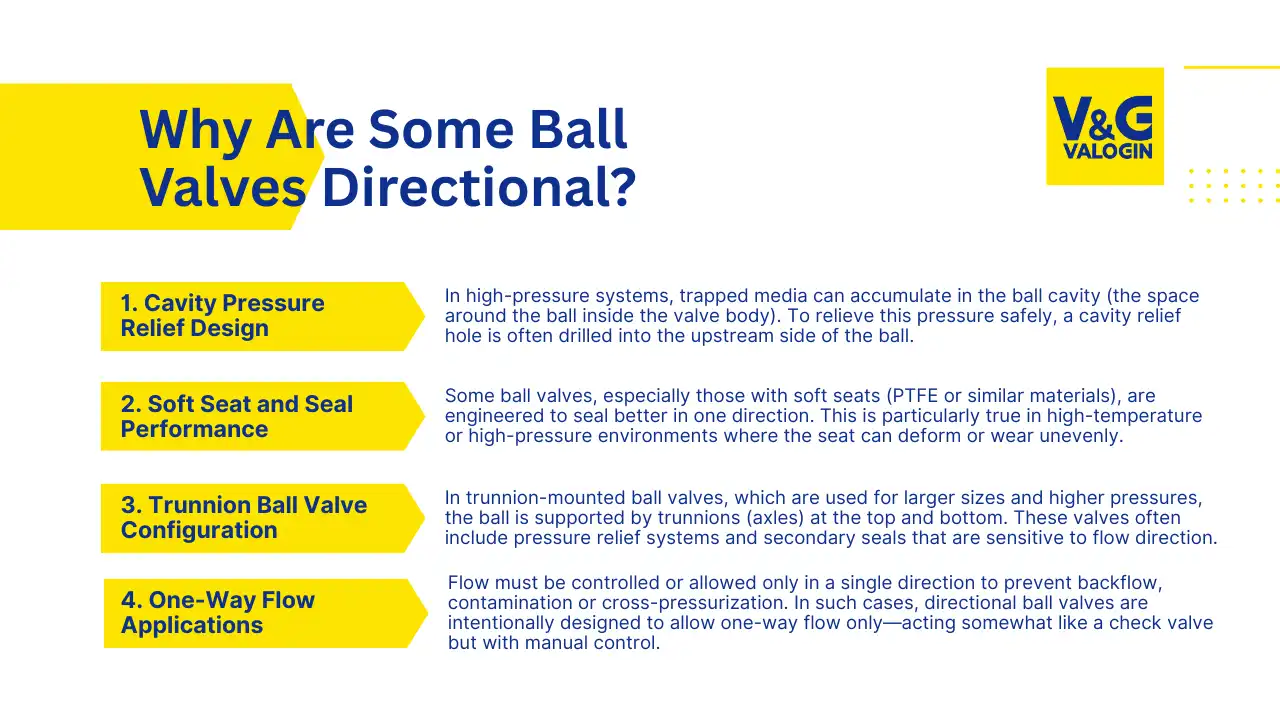

Why Are Some Ball Valves Directional?

Here are the main reasons why some ball valves are directional:

1. Cavity Pressure Relief Design

In high-pressure systems, trapped media can accumulate in the ball cavity (the space around the ball inside the valve body). To relieve this pressure safely, a cavity relief hole is often drilled into the upstream side of the ball. This feature ensures any pressure buildup is directed toward the upstream side rather than the downstream or external areas.

This relief mechanism only works if the valve is installed with the correct flow direction—making the valve unidirectional.

2. Soft Seat and Seal Performance

Some ball valves, especially those with soft seats (PTFE or similar materials), are engineered to seal better in one direction. This is particularly true in high-temperature or high-pressure environments where the seat can deform or wear unevenly.

To ensure a tight shut-off, the valve must be installed according to the manufacturer’s flow direction. If installed backward, the sealing performance may be compromised, causing leakage or seat damage.

3. Trunnion Ball Valve Configuration

In trunnion-mounted ball valves, which are used for larger sizes and higher pressures, the ball is supported by trunnions (axles) at the top and bottom. These valves often include pressure relief systems and secondary seals that are sensitive to flow direction.

Installing the valve incorrectly can lead to excessive pressure buildup or improper operation of the seats, reducing performance and safety.

4. One-Way Flow Applications

In some systems, flow must be controlled or allowed only in a single direction to prevent backflow, contamination or cross-pressurization. In such cases, directional ball valves are intentionally designed to allow one-way flow only—acting somewhat like a check valve but with manual control.

How to Identify Flow Direction on a Ball Valve

Manufacturers typically mark directional ball valves with a flow direction arrow or label on the valve body. This indicates the correct orientation for installation. If no arrow is present, refer to the technical datasheet or product manual to understand the internal structure.

Tips to check flow direction:

-

Look for a flow arrow or “inlet/outlet” engraving.

-

Check for a relief hole in the ball—this side is usually the inlet.

-

In trunnion valves, the seat spring side is usually downstream.

-

Contact the manufacturer if unsure.

Are All Ball Valves Directional?

No. Many standard floating ball valves are bidirectional and can be installed in either direction without issue. These valves are symmetrical in design and the floating ball seals against the downstream seat regardless of flow orientation.

However, when using valves in high-pressure, high-temperature or hazardous applications, always verify whether your valve is directional to avoid operational or safety risks.

Consequences of Incorrect Ball Valve Installation

Installing a directional ball valve in the wrong orientation can lead to:

-

Seat damage and internal leaks

-

Pressure buildup in the valve cavity

-

Seal failure and fluid leakage

-

Reduced service life of the valve

-

Non-compliance with safety standards

These risks make it essential to follow the manufacturer’s guidelines for proper installation.

Conclusion

Not all ball valves are created equal. While some allow flow in both directions, others have a unidirectional design based on specific sealing, pressure relief or application requirements. Understanding why a ball valve is directional and knowing how to install it properly is crucial for the safe, efficient and leak-free operation of your pipeline system.

If you’re unsure about which type of valve to choose or how to install it correctly, contact our experts at Valve.Valogin. We offer a wide range of high-performance ball valves designed for both bidirectional and unidirectional flow, along with expert technical support.

2 Comments

zoritoler imol

December 1, 2023Hey there! I know this is somewhat off topic but I was wondering if you knew where I could find a captcha plugin for my comment form? I’m using the same blog platform as yours and I’m having difficulty finding one? Thanks a lot!

Harold

June 1, 2025Terrific facts. Thank you!

Thanks a lot, Lots of facts.

Reliable postings, Cheers.

Whoa loads of terrific information.

Incredible lots of awesome information!

Excellent forum posts, Kudos!

Thank you. Ample posts.

Superb information, Thanks.

You actually explained this fantastically!

Kudos! Useful stuff.